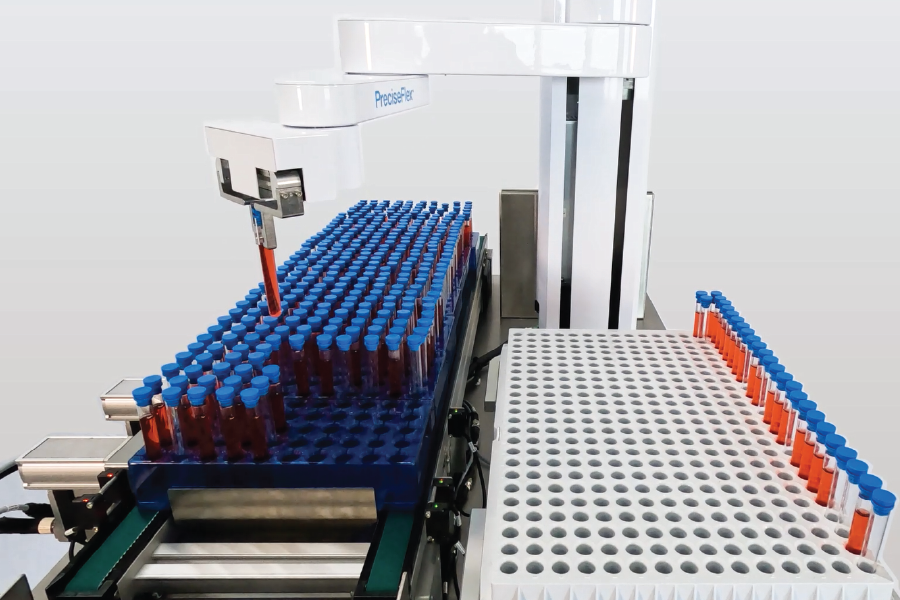

CUSTOMER CASE STUDY

Revolutionizing Diagnostic Vial Re-Racking to Improve Walkaway Time

Precision Diagnostics sought to integrate two distinct processes involving the transfer of vials between different rack formats. Their objective was to enhance operational efficiency by making the process faster, more straightforward, and inherently safer.

To support this goal, they required a solution that would:

- Enable safe and seamless interaction with personnel

- Fit within a compact laboratory footprint

- Reduce operational costs

- Operate using a standard power outlet

- Minimize energy consumption

Advanced Automation Solution with Partner Collaboration

Lab Automation solution built by Arimation Robotics for Precision Diagnostics.

We decided to invest in automating our vial re-racking process primarily to improve efficiency. With this instrument, our staff could simply start the instrument, walk-away and tend to other processes while it ran, eliminating the need for a dedicated resource.

Richard Thomas

Chief Scientific Officer at Precision Diagnostics

Enhanced Worker Efficiency

The PreciseFlex™ 3400 robot operates autonomously, allowing personnel to focus on higher-value tasks and improving overall productivity.

Simplified Setup and Programming

Designed for ease of use, the robot features an intuitive interface and straightforward programming, enabling rapid deployment.

Compact Footprint

With an extended reach and flexible range of motion, the robot maximizes functionality in space-constrained environments.

Collaborative and Safe Operation

Engineered for human interaction, the robot eliminates the need for protective fencing. Its power and force limiting design ensures immediate stoppage upon contact, promoting a safe working environment.

(A risk assessment is always required)

High Speed, Intelligent Handling

The PreciseFlex™ 3400 robot combines speed with precision, automatically adjusting grip force to handle delicate items with care.

Integrated Servo Gripper

The IntelliGuideTM servo gripper design eliminates the need for external sensors. It intelligently detects successful tube acquisition and reattempts if necessary.

Energy Efficient Performance

Powered by a standard wall outlet, the Brooks PreciseFlex™ 3400 consumes minimal energy, contributing to lower operational costs.

Arimation and Brooks collaborated with Precision Diagnostics to understand their challenges and goals. Together, they designed a solution that eliminated manual intervention steps, while meeting the customer’s low power consumption goals. The solution was engineered to integrate seamlessly with the customer’s workflow, providing a compact and safe working environment and reduce overall transfer time. These benefits align closely with the customer’s goals of operational efficiency, workforce safety and process optimization. This collaborative approach and the team’s robust engineering capabilities ensured the solution was both effective and forward-looking.

The PreciseFlex robot is an efficient space user, so it can access pretty much every location in its envelope, which is very unique. The integrated servo gripper makes the integration seamless without any dress packs or cable routing.

Ari Pitkanen

CEO, Arimation Robotics