Automated Test Equipment For Increased Capacity and Reduced Manual Labor

PCBs are getting more complex every year. More layers, tighter pitches, and dense component placement have become the norm, and at the same time customers expect faster turnaround. That leaves manufacturers under pressure to move more boards through test without adding more people.

Automated test equipment is designed to deliver speed and consistency, but in many plants, operators are still loading boards by hand. Each manual touch slows the process, increases the chance of misalignment, and ties up staff who could be focused on higher-value work. When testers aren’t running at their full capacity, the entire line feels the impact.

In this article, we’ll look at what automated test equipment is, how it fits into PCB manufacturing, and practical steps you can take to raise capacity and cut back on manual loading.

What Automated Test Equipment Is and How It Works

Manufacturers rely on automated test equipment (ATE) to increase throughput and improve test quality. When boards are loaded manually, testers often sit idle waiting for the next unit. Instead of running at full design capacity, the operator sets the pace. To capture the true value of ATE, manufacturers need to combine its precision with automated board loading.

Automated test equipment, or ATE, is a computer-controlled system that runs electrical tests automatically. It sends signals into the device under test, measures the responses, and routes signals through switches. The test software then decides whether the board passes or fails. The purpose is consistency: every board is tested the same way, at the same speed, without human error creeping in.

The main building blocks of ATE include:

- Controller and test-executive software that schedule test jobs and minimize idle time

- Sources, meters, and analyzers that generate signals and measure electrical performance, defining the baseline cycle time

- Switching and multiplexers that route signals quickly to different test points

- Fixtures and loaders that connect the board to the tester, which often become the limiting step when loading is manual

ATE is used to test everything from single components to complex integrated circuits and fully assembled PCBs. For boards, the type of access, whether through a bed-of-nails fixture or flying probes, affects both test speed and the amount of operator labor involved.

For a deeper look at these methods, see our PCB Testing Methods and Robotics in High-Mix Manufacturing article.

Where Automatic Test Equipment Fits in PCB Manufacturing

Test methods may vary in coverage and speed, but the way boards are loaded often decides if you can run at full capacity.

In-Circuit Testing (ICT)

ICT uses bed-of-nails fixtures or spring probes to check for shorts, opens, and incorrect components. It can process high volumes, especially in automotive and consumer electronics, but only if boards are fed consistently. In most cases, that level of consistency is only achievable with high-cost, in-line systems designed for continuous operation. For standalone testers, automated loading and clamping provide a more practical way to prevent downtime and reduce operator effort during fixture changes.

Functional Circuit Testing (FCT)

FCT powers up the assembled board to verify performance. Because cycles are longer, stations are often run in parallel. Robotic loading keeps each tester supplied, which is important in industries like telecommunications and industrial controls where functional accuracy is critical.

Flying Probe Testing

Flying probe systems rely on moving probes controlled by software. They are slower per board but valuable for prototypes or high-mix, low-volume production common in medical and aerospace. Automated load and unload with barcode routing minimizes the labor tied to these extended test cycles.

Inspection Systems (AOI/AXI)

AOI checks component placement and solder joints, while AXI verifies hidden features such as BGA solder balls. These machines are usually conveyorized. Aligning ATE loading to the same datum and hand-off point eliminates extra manual touches between inspection and test.

These methods may differ, but they all share the same requirement, boards must be delivered to the tester on time and without delay. Without automated loading, even the most capable ICT or functional tester ends up waiting on an operator. Adding automation turns theoretical test coverage into practical throughput gains, allowing more boards per hour without extra staff.

Manual Loading Limits Capacity and Drives Labor Variability

By automating the loading step, testers stay closer to their rated throughput, variability is reduced, and operators can apply their skills to higher-value work.

Manual loading may seem like a small task, but across a shift it can make the difference between a tester running at full design speed or falling far short. Automated test equipment is built to deliver repeatability, yet when every board must be placed by hand the real pace is determined by the operator.

Lost Capacity from Idle Time

Idle time is one of the biggest losses. Even a short delay of ten seconds per board adds up quickly. On a run of 1,000 boards, that is nearly three hours of lost test capacity. The effect is magnified when one operator is responsible for feeding multiple testers, leading to queues and slower overall throughput.

Quality Risks from Inconsistent Loading

Variability is another hidden cost. Manual placement increases the chance of slight misalignment, which can cause contact retries or false failures. In some cases, boards are damaged during handling, resulting in rework or scrap that directly affects margins.

Labor Burden from Repetitive Tasks

The labor burden is also significant. Skilled technicians end up spending much of their shift performing repetitive transfers instead of focusing on troubleshooting or process improvement. This is a poor use of valuable talent, and over time it contributes to fatigue and higher turnover.

For these reasons, many manufacturers have turned to magazine loaders, unloaders, and robotic systems that maintain a steady flow of boards into and out of test equipment.

How to Improve ATE Efficiency With Loading Automation

Automated test systems only reach their full value when the test cell is treated like a complete mini-line. That means consistent board presentation, reliable loading, connected data, and balanced cycles. By addressing these areas, manufacturers can move more boards per hour while reducing the labor tied up in repetitive tasks.

Step 1 — Standardize Board Handoff

Consistent presentation is the foundation of efficient testing. Using fixtures or conveyors with a common datum and height helps boards seat quickly and reduces retries. Synchronizing equipment with machine-to-machine signals prevents testers from starving or blocking. This lowers the need for operator interventions.

Step 2 — Automate Loading and Unloading

Manual transfers are the biggest limiter of capacity. Pairing magazine loaders or unloaders with robotic systems keeps testers supplied at a steady rate. With PCB-edge grippers and vision tools, boards are positioned accurately on the first try. This increases throughput and eliminates re-seating work for operators.

Step 3 — Connect Test Data and Traceability

Every board benefits from serialization. Barcodes or RFID scanned at load provide a unique ID that links each result back to the device. Feeding those results directly into MES or ERP systems speeds up root-cause analysis and eliminates manual log entry. Operators spend less time on paperwork and more time on process improvement.

Step 4 — Balance Cycle Times and Buffers

A mismatch between test cycle time and loading cycle time creates bottlenecks. Measuring both allows manufacturers to right-size buffers so testers remain fully utilized. With the right buffers in place, operators are not rushing to catch up or waiting for machines to finish.

Step 5 — Optimize Changeovers and Fixtures

Downtime between product runs can quietly eat into capacity. Quick-change nests and automated clamps reduce the steps and tools required for changeovers. For prototypes or short runs, flying probe testers help avoid fixture builds altogether, allowing faster ramps without tying up staff.

Step 6 — Safety and Ergonomics

Collaborative robots make automation practical in tight production spaces. By working safely alongside people, they allow continuous operation without heavy guarding. Operators are redeployed to higher-value tasks such as troubleshooting or repair instead of repetitive transfers.

From Actions to Measurement

Each of these steps is actionable, but their real value comes from tracking results. Measuring the right KPIs shows whether automation is increasing throughput and reducing manual work as intended.

Metrics to Track

| Metric | What It Measures | Impact on Capacity | Impact on Labor |

| Boards per Hour | Number of boards tested in a given time | Direct measure of throughput | Shows reduction in manual loading bottlenecks |

| Tester Utilization (%) | Percent of time testers are actively running | Higher utilization = fewer idle gaps | Less operator intervention needed |

| Manual Touches per Board | How often staff handle a board | Fewer touches improve flow and consistency | Reduces repetitive low-value tasks |

| Changeover Time | Time lost switching between products | Faster changeovers increase available capacity | Operators spend less time on setup |

| First-Pass Yield | Percent of boards passing without re-test | High yield keeps capacity focused on new boards | Less rework effort for staff |

| Mean Time Between Assists (MTBA) | Time between when operators must intervene | Longer MTBA means smoother automation | Staff can focus on troubleshooting, not babysitting |

Automating Test Equipment Loading With PreciseFlex

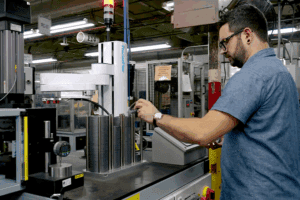

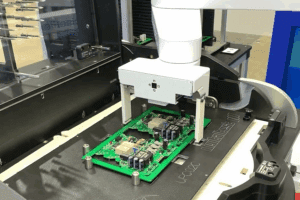

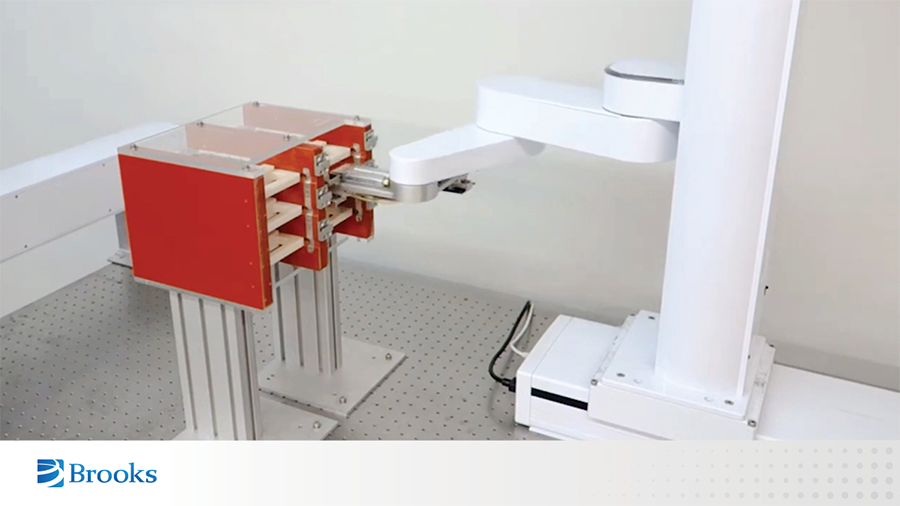

PreciseFlex robots apply these principles directly in PCB test cells. They are built for loading ICT, FCT, and flying probe testers, providing a compact vertical reach that fits racks, fixtures, and enclosed testers where space is limited.

By keeping testers continuously fed, PreciseFlex helps achieve the boards per hour that ATE systems are designed for. Operators are freed from manual loading and can focus on higher-value work such as debugging or quality checks.

PreciseFlex robots are engineered for reliability with long design life and low power consumption, which reduces both downtime and operating costs. Embedded controls and vision-enabled gripping simplify integration and ensure first-time placement, reducing the setup effort that often slows deployment.

By automating the loading step, PreciseFlex closes the gap and transforms theoretical test capacity into real, daily output.

Learn more about automating electronic handling in our whitepaper.

Scaling PCB Testing With Automated Loading

Automated test equipment is built to deliver consistency and accuracy, but manual loading prevents it from running at full capacity. Each board that waits for an operator lowers throughput and increases the amount of labor tied up in repetitive work.

Automating the loading step is the most direct way to increase test capacity while reducing manual labor. Testers operate closer to their rated boards per hour, results are more consistent, and skilled staff can focus on higher-value work like troubleshooting and process improvement.

Start Automating Today

Get in touch with our automation team to learn how PreciseFlexTM robots can automate loading in your test cells and help you model the impact on both capacity and labor.