Electronics Manufacturing Challenges Making Test Automation Essential

You’re running an electronic manufacturing services (EMS) operation built for flexibility. High-volume manufacturers invested millions in inline test automation. But you chose offline test stations because your business needs flexibility to handle diverse products.

But that flexibility comes with a constraint. Your offline test stations still require manual loading and unloading. It’s one of the few remaining manual operations in the manufacturing of printed circuit boards (PCBs) and consumer electronics.

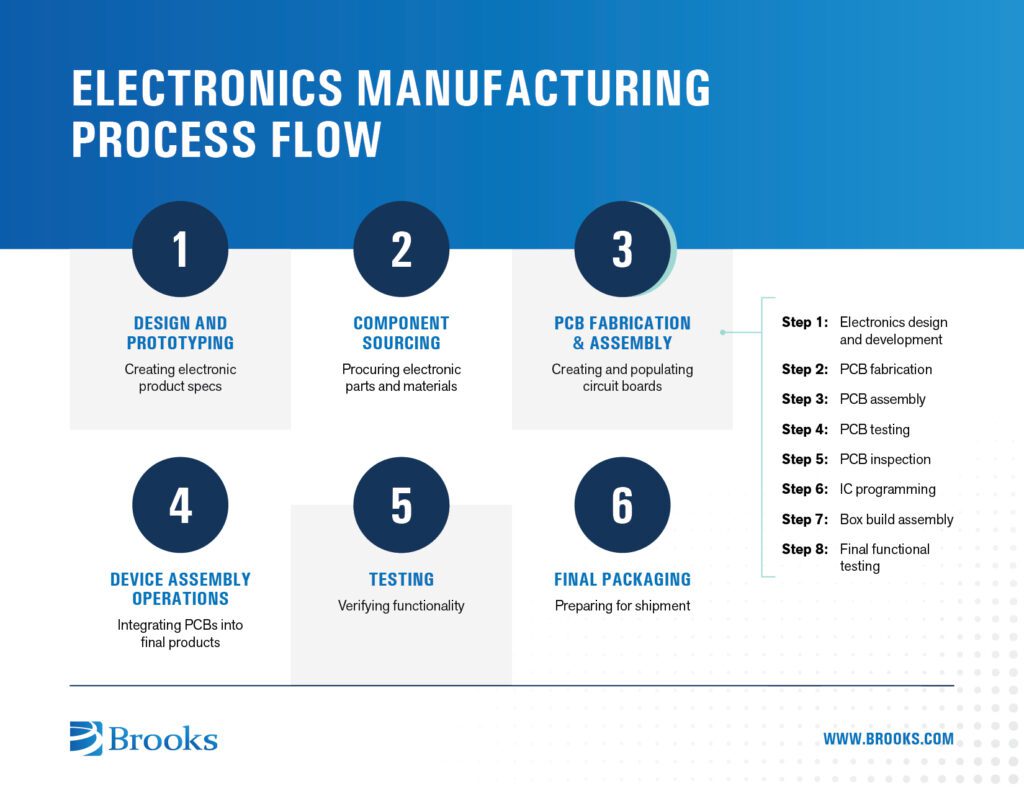

Electronics manufacturing follows a step-by-step process:

- design and prototyping (creating electronic product specifications),

- component sourcing (procuring electronic parts and materials),

- PCB fabrication and assembly (creating and populating circuit boards),

- device assembly operations (integrating PCBs into final products),

- testing (verifying functionality),

- and final packaging (preparing for shipment).

Electronic manufacturing process steps

Pick-and-place machines, robotic assembly systems, and automated packaging lines now handle most stages. Testing operations in EMS companies remain manual, especially for high-mix production.

These manual operations occur during In-Circuit Testing (ICT), Functional Circuit Testing (FCT), flash programming, and burn-in processes. They verify quality and functionality before final packaging.

For years, this made sense. Testing had lower volumes, variable setups, and less clear ROI than high-speed assembly lines. Now, this manual bottleneck is colliding with industry pressures that make manual operations unsustainable.

Today’s Industry Trends Create New Challenges for Traditional EMS Models

Three industry trends are creating challenges that make manual operations unprofitable:

- supply chains moving closer to customers,

- faster product changes,

- and severe worker shortages.

Many EMS companies built successful businesses around manual flexibility. Your operators could adapt to any product, handle complex setups, and troubleshoot issues that automated systems couldn’t. This approach worked when labor was abundant and customers accepted longer lead times.

But these industry trends now create daily operational challenges. Worker shortages mean you can’t reliably staff test stations. Rising costs from domestic production squeeze margins. Faster product changes require more frequent changeovers that manual operations can’t handle efficiently.

These new realities point toward automation, especially for manual test loading operations.

Workforce Crisis and Rising Labor Costs

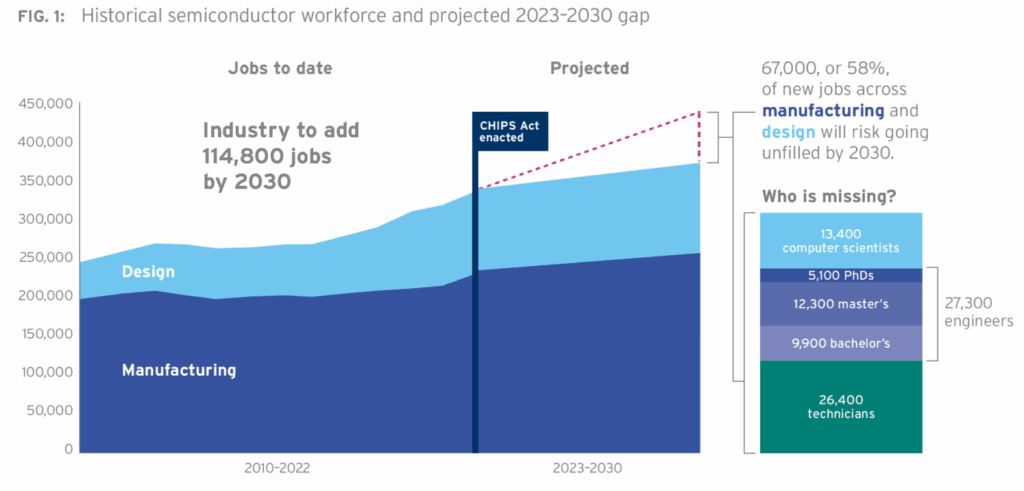

The semiconductor industry alone faces a 1.4 million job gap by 2030. EMS markets are growing from $567 billion to $857 billion, which makes manual operations unsustainable.

Historical semiconductor workforce and projected 2023-2030 gap

66% of electronics manufacturers report rising labor costs impacting operations. Material costs, shipping expenses, and regulatory compliance costs compound the financial pressure. This cost inflation forces manufacturers to absorb margin pressure or pass costs to customers in competitive markets.

The workforce that remains is expensive and hard to retain. Two-thirds of IPC’s U.S. members report that the inability to find skilled workers limits their growth. Even experienced operators retire or move to higher-paying industries.

Supply Chain and Market Pressures

Electronics manufacturers are moving production closer to customers. This increases labor costs and requires more efficient operations to maintain competitive margins.

Geopolitical tensions and trade policies drive companies to reconsider global supply chains. Near-shoring and “China Plus One” strategies relocate production closer to end markets while bringing new challenges. Companies can’t rely on low overseas labor rates anymore to maintain margins.

Rapid technological advancement creates shorter product lifecycles. Companies need to handle more product mix and shorter production runs. This also requires more agility on production lines and faster changeovers.

Manual Test Operations Create Staffing Dependencies That Limit Growth

Many EMS companies optimized their manual test operations over years. Your skilled operators know every product and can troubleshoot issues that would stop automated systems. This worked well when you had consistent, experienced staff.

But workflow consistency has become a bigger operational risk than rising labor costs alone. When your key operators show up, manual operations work fine. The problem comes when they call in sick, quit, or retire. Suddenly your optimized process becomes unreliable.

For mixed-product EMS operations, this staffing dependency creates unpredictable workflow. Automated systems deliver predictable cycle times regardless of who’s on shift. Manual test handling operations depend entirely on operator availability and experience.

Most EMS face inconsistencies from loading and unloading offline test equipment. High-volume production lines achieve full automation with inline testing. But mixed-product operations rely on offline testers requiring manual handling. This manual operation limits electronics manufacturing throughput.

Manual operations introduce variations in the process. Operators juggle many priorities, creating inconsistent cycle times as they bounce between stations. Handling sensitive electronic components by hand also introduces quality risks.

Moreover, operators often wait idle during longer test cycles, lasting several minutes. This wastes valuable labor resources when skilled technicians are already scarce and expensive.

Test Automation ROI Is Clearer Than Most EMS Companies Think

Many EMS companies think test automation ROI is hard to calculate. The volumes are lower and benefits are less obvious than SMT automation. Traditional metrics miss the full picture. You need to account for reduced errors, eliminated overtime, and workforce reliability. Automated systems also provide consistent data capture on test performance, quality metrics, and throughput that enables data-driven decisions.

Automated test loading systems deliver measurable cost savings and productivity gains. Most systems pay for themselves in 16–20 months. This might seem like a long time for capital investment. But this payback period is actually faster than most manufacturing automation projects.

The savings gap widens as labor costs rise while automation helps maintain production costs. PreciseFlex robots prove this across EMS operations worldwide. They achieve ROI despite differences in labor rates and workflows:

- Mexico operations reach 18-month breakeven with $35K annual labor costs,

- US operations reach 20-month breakeven with $67.5K annual labor costs,

- And Germany operations hit 16-month breakeven with higher labor rates.

These payback periods assume conservative operational models. The reality often exceeds projections because companies discover additional benefits they hadn’t calculated.

Consistent cycle times and elimination of operator delays boost output without adding shifts. Elimination of handling errors reduces the need for rework. Reduced repetitive stress injury claims result in lower insurance and replacement costs.

The initial ROI calculation only tells part of the story. As labor costs continue rising, automated systems help maintain consistent operational costs. Companies automating early will see bigger savings each year.

To explore how test handling automation can address your specific production challenges, contact PreciseFlex robot application experts.

Offline Test Automation Solves Floor Space Constraints With Human-Scale Robots

Many EMS companies avoided test automation because traditional systems were too bulky. Older automation required massive floor space for safety barriers, conveyor systems, and large equipment. Most EMS facilities couldn’t afford to give up that much production space.

But human-scale collaborative robots like PreciseFlex represent a new approach. These robots work within existing test station footprints without safety barriers or major layout changes. They fit into space-constrained EMS operations.

This solves a real problem for EMS companies. Floor space costs money. Facility expansion requires significant capital investment. Companies need to maximize production capacity without expanding their buildings.

Single offline robots can serve many test stations while preserving scarce floor space. One of our EMS customers previously relied on an operator to manage 4 test stations. The same manufacturer now operates those test stations in a more compact space, thanks to PreciseFlex robots. This means maintaining testing capacity while reducing the floor footprint and freeing up the operator.

The Case for Automating Test Equipment Handling

EMS companies implementing offline test automation today gain sustainable competitive advantage. Those waiting face widening cost gaps and operational risks.

Some EMS leaders think they can wait for better technology or clearer ROI. But waiting now means missing compounding benefits as labor costs rise 4.6% annually while automation costs stay fixed.

The evidence is clear. Human-scale robots solve floor space constraints that once blocked automation. Systems pay for themselves in 16-20 months across different regions. Companies double testing capacity while competitors struggle with manual bottlenecks.

This isn’t just about replacing workers. It’s about operational reliability when skilled operators leave or retire. Companies automating now lock in savings that grow each year.

Ready to eliminate your testing bottleneck?

Download the Automating Electronic Test whitepaper to see detailed implementation strategies, regional cost analysis and proven case studies.

We can help identify your highest-impact automation opportunity!

Let’s discuss how to overcome your manufacturing challenges with automation.