Improving Electronics Quality Control by Eliminating Manual Handling

You’re reviewing yesterday’s quality metrics when your phone rings. It’s your biggest customer: “We’re seeing intermittent failures on last week’s batch. Same issue we discussed six months ago.”

You walk the floor with your quality engineer. Components passed incoming inspection. Assembly data looks perfect. Test results were in spec. Your ISO procedures were followed exactly.

But then you notice the small differences. Operators handle boards differently during changeovers. They load fixtures with slight variations. They use inconsistent pressure during manual transfers.

Your procedures are documented. Training is current. The operators are skilled.

But protocols can’t eliminate the micro-variations in how humans handle consumer electronics and industrial products. And those inconsistencies? They’re showing up later as field failures.

Quality control in electronics manufacturing (link to last article) relies on comprehensive strategies:

- Incoming inspection (IQC) – validating component specifications and material quality before production

- Process control – monitoring manufacturing parameters and maintaining consistent operations

- Statistical process control (SPC) – using statistics to track performance and detect process drift

- End-of-line testing – verifying final product functionality and performance standards

These methods work well to keep products reliable and meet the standards electronics need. But manual handling creates variables that quality control methods cannot stop from happening.

Manual handling persists throughout manufacturing and the supply chain: material movement, changeovers, rework operations, and testing. Each step adds differences that quality systems find too late. They catch problems after they happen instead of preventing them.

The biggest opportunity is in testing operations. Manual handling happens at the final quality check. To understand why prevention beats detection, you need to see how this affects your entire operation.

Manual Handling Operations Create Quality Control Challenges For EMS Manufacturing

Manual operations create differences that your quality control methods can find but cannot prevent. This happens even when workers follow your best procedures.

Walk your production floor and you’ll see various automation systems already used:

- Pick-and-place machines handle component placement with microscopic precision,

- Reflow ovens maintain temperature profiles within tight tolerances,

- Automated optical inspection systems catch solder defects that human eyes would miss.

Yet between these automated islands, manual steps remain. Operators manually transfer work-in-process, while technicians hand-load components during changeovers. Quality inspectors lift boards for visual examination. And test operators position units in fixtures dozens of times per shift.

Now, you might be thinking: “But we have documented procedures for all of this.”

You’re absolutely right. Each manual operation follows documented work instructions.

- Your ISO 9001 system defines standard operating protocols (SOPs) for material handling.

- IPC training ensures operators understand proper electrostatic discharge (ESD) guidelines.

- Work instructions specify grip points and handling techniques.

And your procedures work. They significantly reduce handling errors and maintain consistency most of the time.

Procedures can’t eliminate human variability entirely

The challenge isn’t that your procedures are inadequate.

The challenge is that protocols cannot eliminate human variability entirely.

One operator applies slightly more pressure when loading delicate connectors. Another positions boards with minor angular differences during visual inspection. A third moves faster during rush periods, creating subtle handling stress that accumulates over time.

These aren’t procedure violations. These happen naturally because of how humans are built. Even the best training can’t completely eliminate them.

Your QC framework excels at managing automated processes. Statistical process control (SPC) monitors machine parameters in real-time. IQC validates component specifications before they enter production. Process management systems track every automated operation with precision.

The gap emerges where human hands touch sensitive electronics. Quality management methods detect manual handling variability (failed tests, visual defects, field failures). Still, they cannot prevent the micro-inconsistencies that create these problems in the first place.

Consider your most recent quality issue. Components passed receiving inspection. Automated assembly data showed perfect placement.

Yet something went wrong between process steps. The investigation probably found handling problems. These included:

- static electricity damage during transfer,

- too much pressure during loading,

- or contamination from touching the boards.

This detection-versus-prevention limitation compounds across your manufacturing process. Manual handling errors in early operations propagate through downstream automated processes. They are creating quality challenges that proven systems can identify but cannot stop from occurring.

The highest-stakes manual operations occur during testing. This is where handling variation impacts your final quality gate before products reach customers.

Why Manual Handling Creates the Highest Quality Control Risk

Manual test handling happens at your final quality check, where mistakes cost the most and are hardest to fix.

You might think all manual handling risks are roughly equal. A mishandled board early in assembly creates the same quality issue as one mishandled during testing.

Wrong. That’s not how manufacturing economics work.

Testing represents your highest-stakes manual operation for three critical reasons:

1. Final Quality Gate Impact

If test operators accidentally damage boards with static or rough handling, there’s no other process to catch it. Defective units reach customers, leading to field failures. This is damaging your reputation and costing money in warranty claims.

2. Peak Cost Discovery

Early-stage handling errors might scrap a bare printed circuit board (PCB) worth $15. But when test handling damages a fully assembled unit worth $150–$500+, the labor, component costs, and processing time make it far more expensive.

3. Limited Recovery Options

You can fix assembly mistakes. You can correct wrong component placement. But test handling damage is different. Tiny cracks from too much pressure, hidden static damage, or bent connectors can’t be fixed reliably. Products either pass tests but fail later in the field, or require full rebuilds that destroy profitability.

Manual test handling creates four specific variability sources that amplify these risks:

- ESD exposure causes latent failures that appear weeks after shipping

- Inconsistent fixture loading creates test repeatability issues and accelerates equipment wear

- Variable handling pressure introduces mechanical stress that compromises long-term reliability

- When cycle times vary, it creates production slowdowns that pressure operators to rush, leading to more mistakes

Your test operators are skilled professionals. They follow procedures carefully. But small variations are unavoidable when humans perform repetitive tasks. Quality systems only detect the damage after it occurs. When it’s costly to fix and customers feel the biggest impact.

Learn more about automating electronic handling in our whitepaper

How Automated Test Handling Completes Your Prevention Strategy

Robotic test handling transforms your final quality checkpoint into a prevention step. This changes your operation from reactive to proactive quality control.

But one important gap remains: manual test handling still only catches problems instead of preventing them. This happens after your other prevention systems have already done their work.

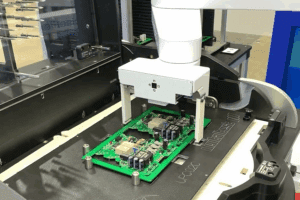

PreciseFlex robots fix these problems by preventing damage instead of just finding it. This completes your quality control plan at the final testing stage.

| Cost Factor | Manual Handling Impact | Automation Benefit |

| Labor | $35 – $67K annually for fixture loading | Redeploy to higher-value tasks |

| Handling Errors | $150 – $500+ per damaged unit | Eliminated through consistent positioning |

| Warranty Claims | $1,000+ per field failure | Prevented via ESD-safe grippers |

| Throughput | Variable cycle times disrupt schedules | Predictable timing enables planning |

Technical Prevention Capabilities

- Placement repeatability (ex., ±0.05-0.08 mm) ensures identical positioning across every test cycle

- ESD-compliant grippers prevent ESD exposure before it occurs

- Consistent handling pressure prevents micro-stress and connector damage that manual operations cannot avoid

Operational Benefits

Consistent timing eliminates the production slowdowns that mess up schedules and delivery promises. Single robots can handle multiple test stations while saving valuable floor space.

One electronics manufacturing services (EMS) customer used to need an operator to manage 4 test stations. The same company now runs those test stations in less space, thanks to PreciseFlex robots. This means automating the testing work while using less floor space and freeing up the operator for more important tasks.

Implementation Advantages

Human-scale robots fit into your existing test stations without safety barriers or layout changes. This solves the floor space constraints that previously blocked automation adoption. Implementation doesn’t require facility expansion or massive workflow disruption.

Investment Returns Across Regions:

| Region | Annual Labor Cost | Payback Period |

| Mexico | $35K | 18 months |

| United States | $67.5K | 20 months |

| Germany | Higher rates | 16 months |

These estimates typically miss the full benefits. They don’t include savings from lower insurance costs, no overtime pay, and happy customers from more reliable products.

The Strategic Completion

Automated test handling extends your current prevention methods to the final testing step. This removes the last checkpoint that only finds problems instead of preventing them.

Your quality control investments now work consistently from start to finish. Every stage reinforces reliability, rather than simply catching errors after they occur.

Most importantly, automation frees your skilled technicians for more important work. They can focus on problem-solving and improvements that need human thinking, not just human hands.

Start Where Manual Handling Creates Maximum Risk

Automated test handling delivers measurable ROI while addressing your most critical operational challenges.

Manual handling still happens throughout electronics manufacturing. But test handling creates your biggest quality control risk. It happens at your final quality check, where problems bypass other detection methods and go straight to customers.

Your quality control methods work great for managing automated processes. But they can’t prevent the small differences that human handling creates. Even skilled operators following proper procedures create small inconsistencies. Detection systems only find these problems after damage happens.

The results of automating handling operations are tangible:

- Payback in 16–20 months across regions,

- Elimination of costly handling errors,

- Prevention of warranty claims exceeding $1,000 per incident,

- And better use of floor space.

Most importantly, automation frees operators to focus on higher-value tasks.

Handling automation at this critical step completes your quality control plan.

Looking to improve the quality of your test operations?

Discover how to improve quality standards without disrupting your current setup.