Automate Microplate Handling Without Expanding Your Lab Footprint

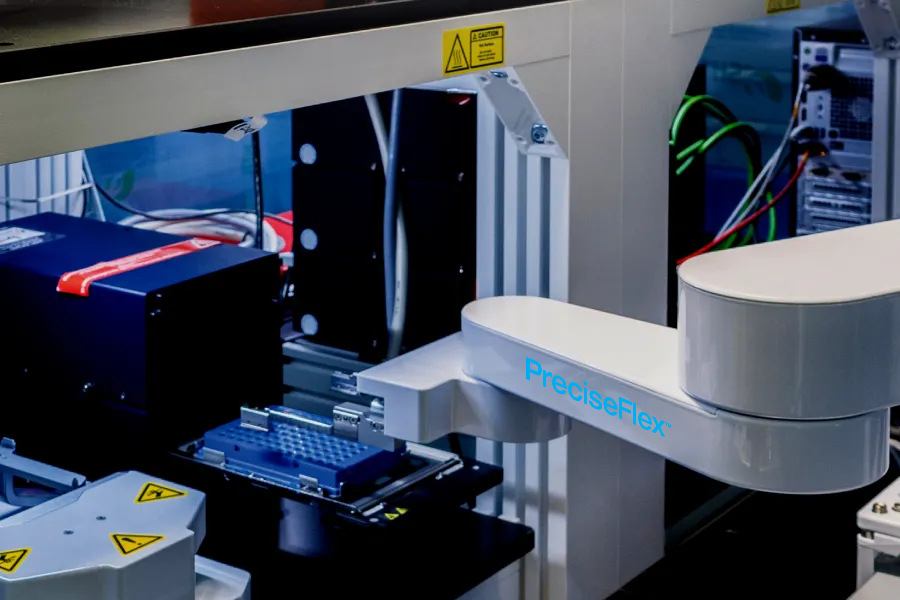

Manual transfers waste skilled labor and risk sample errors. PreciseFlex robots move plates consistently and safely in the same footprint as your technicians.

Manual Microplate Handling Slows Your Lab Down

The hidden costs of hand transfers

Every plate moved by hand risks cross-contamination, inconsistent timing, or dropped samples. Those small errors undermine throughput and assay integrity.

Big systems aren’t the answer

Traditional automation can be bulky, rigid, and expensive. Many labs don’t have the footprint or budget for a full overhaul.

People can’t scale

When throughput grows, manual handling creates delays and staffing bottlenecks that slow results across the lab.

The PreciseFlex Way to Automate Microplate Workflows

Automation that adapts to your lab

Handling microplates by hand slows workflows and introduces avoidable risks. Traditional lab automation systems can be bulky, rigid, and costly to implement. PreciseFlex robots give you a flexible footprint-friendly alternative that integrates seamlessly into your lab without infrastructure changes.

Safe for fragile labware

With gentle motion and servo-controlled grippers, PreciseFlex robots move SBS plates and other labware consistently and securely. This reduces the risk of cracked plates, lost samples or contamination that can compromise assay integrity.

Compact and capable

Built with a cylindrical workspace and extended vertical reach, PreciseFlex robots easily access stacked analyzers, incubators, and other instruments. They bring automation into tight lab environments where traditional gantries or large 6-axis robots simply won’t fit.

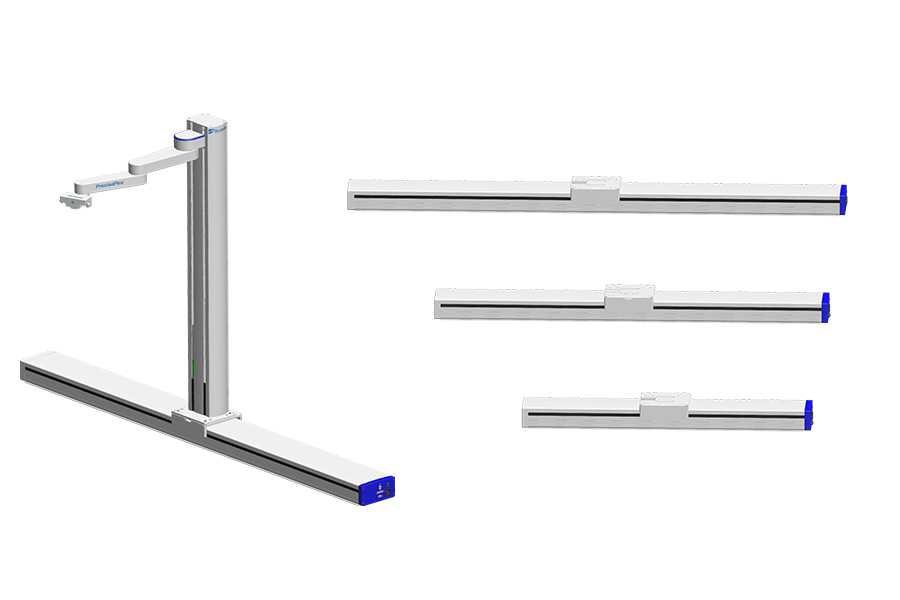

Robots Built for Microplate Handling in Any Lab Setup

Whether you’re transferring SBS plates into analyzers, managing cold storage access, or moving trays between stacked instruments, there’s a PreciseFlex robot sized and configured to fit your workflow.

Each model delivers human-scale automation: compact design, precise motion, and seamless integration into tight lab environments.

PreciseFlex 400

(0.5 kg payload)

Lightweight and efficient, the PreciseFlex 400 handles SBS plate transfers in tight benchtop or shelf setups. Its small footprint makes it perfect for space-limited labs.

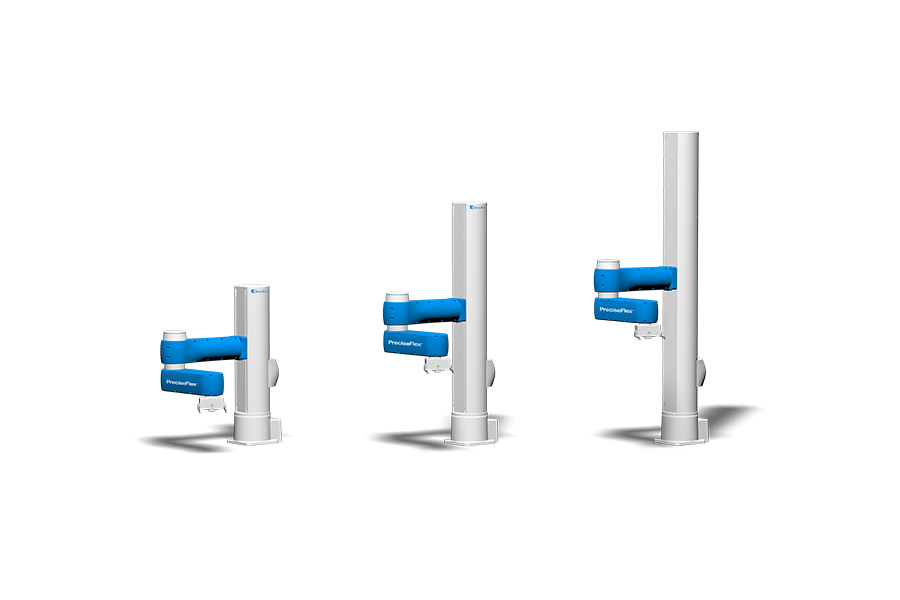

PreciseFlex c5

(5 kg payload)

Cylindrical working volume for higher instrument density and higher horizontal reach for stacked instruments. 5 kg payload (w/o gripper).

PreciseFlex 3400

(3 kg payload)

With vertical reach up to 1160 mm, the PreciseFlex 3400 is ideal for accessing tall analyzers, racks or shelving systems. It brings extended reach without consuming valuable floor space.

PreciseFlex c10

(10 kg payload)

With a 10 kg payload, the PreciseFlex c10 is built for multi-plate carriers or heavier labware. Direct-drive motors ensure smooth motion, durability and low maintenance.

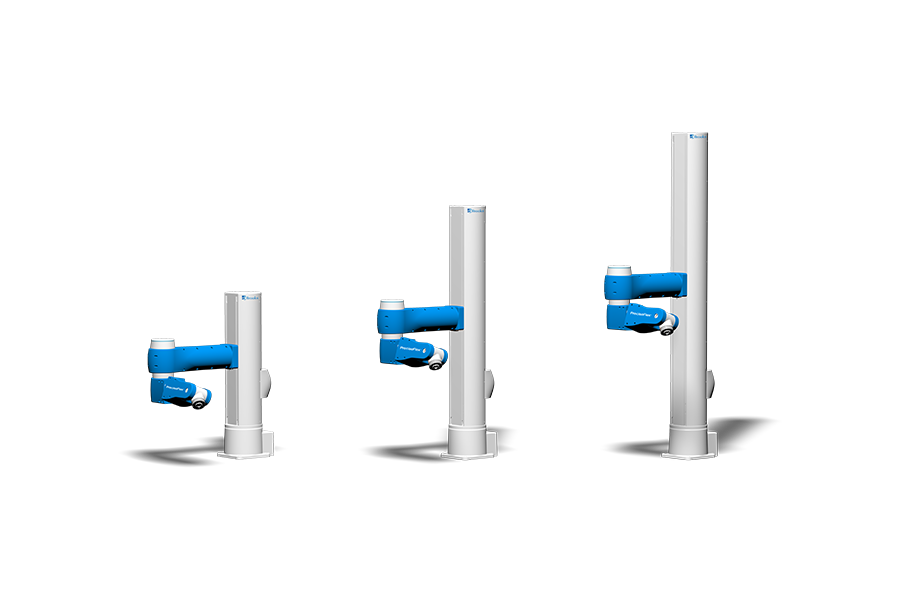

PreciseFlex c8A

(8 kg payload)

The PreciseFlex c8A delivers multi-axis flexibility for angled or side-access instruments. Its cylindrical footprint supports crowded or stacked lab environments without requiring layout changes.

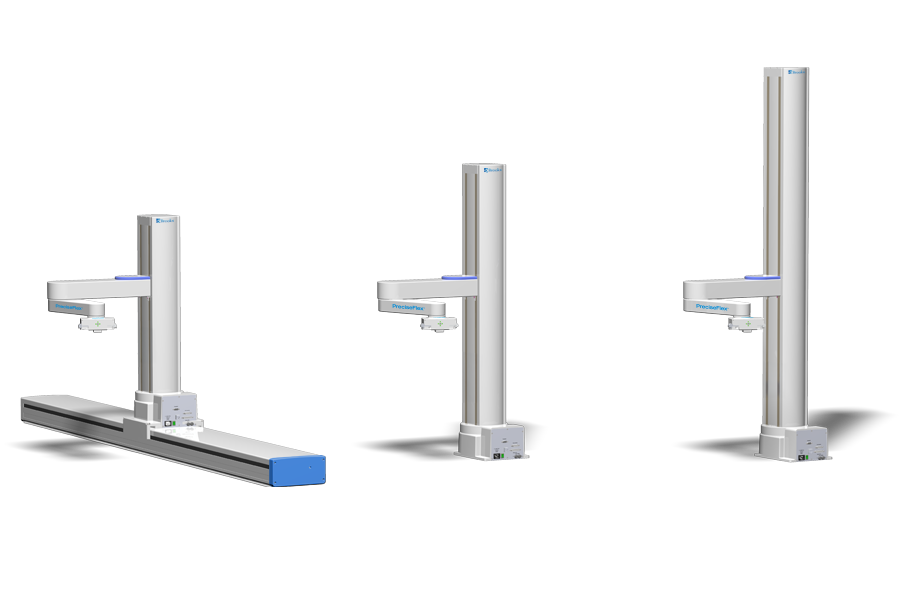

Linear Rail

Available in 1.0 – 2.0m lengths, the linear rail expands reach across multiple assay stations. It enables high-throughput workflows without increasing system footprint.

Why Choose PreciseFlex Over Traditional Plate Handlers?

Traditional plate stackers and gantry systems were designed for fixed, high-volume labs. They take up valuable floor space, lock you into rigid layouts, and require significant guarding and integration effort. When workflows change, they’re costly to adapt or worse, they get abandoned.

PreciseFlex robots are different. They deliver automation that matches the reality of modern labs: compact, flexible, and safe to use side-by-side with technicians. Instead of redesigning your space, you drop them in where your people already work. And when your workflows evolve, they can be redeployed quickly without expensive engineering.

That’s why labs worldwide choose PreciseFlex over conventional handlers — they get reliable automation today, with the freedom to adapt tomorrow.

Smarter Than Just a Robot

IntelliGuideTM Vision

Plates aren’t always placed perfectly. That’s how we see it.

IntelliGuide Vision detects and aligns SBS and microtiter plates in real time—even when trays shift or plates vary slightly. It supports barcode scanning, presence checks, and error-proofing to keep workflows accurate and reliable.

Advanced Servo Grippers

Gentle with labware. Firm with consistency.

IntelliGuide Servo grippers apply just the right amount of force to handle microplates safely, preventing cracked wells or lost samples. Auto-teach functionality accelerates setup, reduces engineering effort, and ensures repeatable handling across plate formats.

Seamless Connectivity

TCS API Library

Our TCS API library provides seamless connectivity and control of PreciseFlex robots from a wide range of workflow and scheduling software. This includes Green Button Go, Cellario OS, Genera, LINQ, PlateWorks, LabView, and others. TCS APIs are written in GPL, are open-source and fully customizable.

Maximize Your Lab’s Output Without Sacrificing Flexibility

Keep instruments running without intervention

Enable lights-out microplate loading and unloading to extend uptime and maintain throughput across shifts.

Protect plates from damage and variability

Low-inertia motion and force-sensitive grippers handle SBS plates gently and consistently.

Fit automation into your existing footprint

PreciseFlex robots integrate into benchtops, stacked systems, or mobile carts without requiring facility redesign.

Eliminate manual errors and mix-ups

Accurate placement and repeatable motion improves sample traceability and reduces cross-contamination.

Microplate Handling Applications Simplified with PreciseFlex Robots

Loading and unloading analyzers, washers, and readers

Transfer SBS plates into plate readers, washers and analyzers with precise alignment and smooth motion. Prevent jams and misplacements that can delay assays or compromise accuracy.

Sample prep for high-throughput screening

Automate repetitive transfers between pipetting stations and screening workflows to keep discovery pipelines moving. Compact robots reduce bottlenecks and support drug development at scale.

Managing cold storage access (Refrigerators, Incubators)

Retrieve and place plates into refrigerators or incubators without obstructing airflow or workspace. Consistent robotic handling preserves storage conditions and minimizes contamination risk.

Transfer between stacked instruments or carousel systems

Access vertically stacked or carousel-configured instruments with consistent accuracy. PreciseFlex robots reach multiple tiers without the footprint or rigidity of gantry systems.

Ready to Automate Microplate Handling in Your Lab?

Talk to our application specialists about flexible, footprint-friendly microplate automation and how it can work for your lab.

Frequently Asked Questions

Do I need a large automation system for microplate handling?

No. PreciseFlex robots integrate compactly with embedded controls, so you can add automation without expanding your lab footprint.

Can it handle SBS-format microplates and deep well plates?

Yes. IntelliGuide Vision and servo grippers accommodate SBS plates in portrait and landscape orientations with variable grip force for safe, repeatable handling.

Do I need to code robot motion paths?

Not usually. With our TCS API, PreciseFlex robots are seamlessly controlled from third party workflow or scheduling software, such as Cellario, Green Button Go, Genera, LINQ and others.

What if I need to move plates between instruments on different benches?

PreciseFlex robots can be mounted on a linear rail, extending reach across multiple stations or instruments.

Can this work on mobile carts or AMRs?

Yes. With low power usage and embedded controls, PreciseFlex robots are ideal for mobile lab setups and flexible workflows. This includes presenting samples on a roll-up cart or mounting a PreciseFlex robot onto an Autonomous Mobile Robot (AMR).