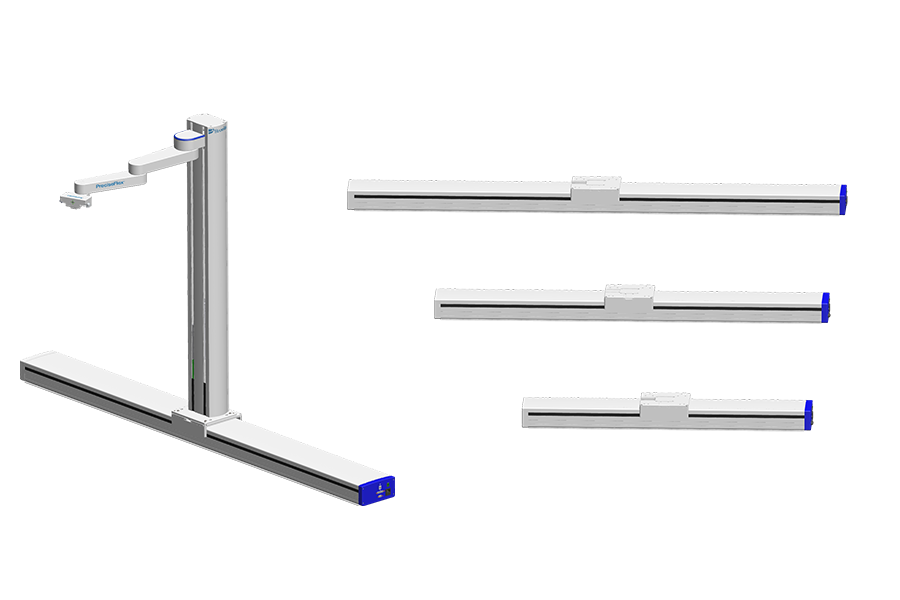

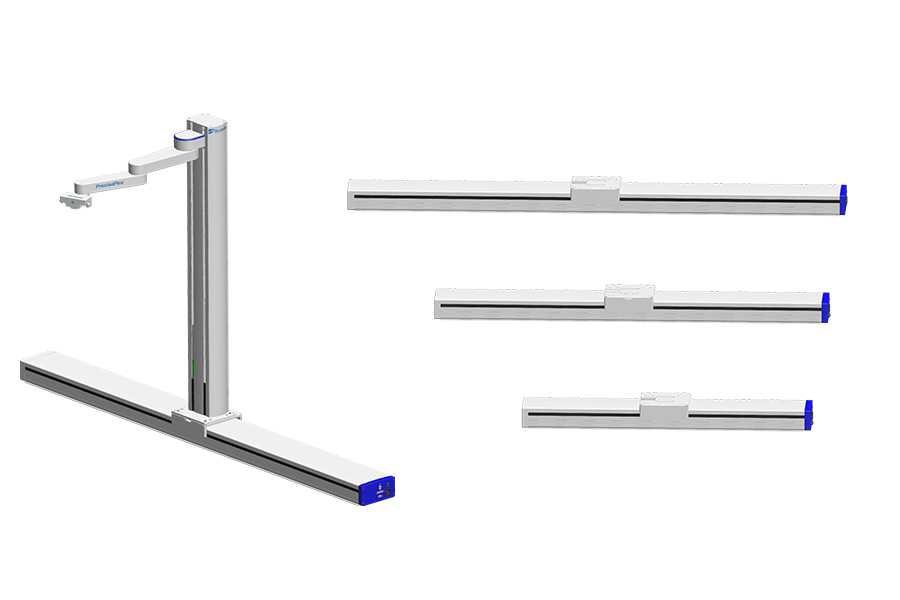

Linear Rails

PreciseFlex robots can be ordered with an optional linear rail to extend the horizontal reach of the robot. Available in 1000, 1500, and 2000 mm travel distances, linear rails can be ordered with PreciseFlex 400, PreciseFlex 3400, PreciseFlex c3, and PreciseFlex c5 robots.

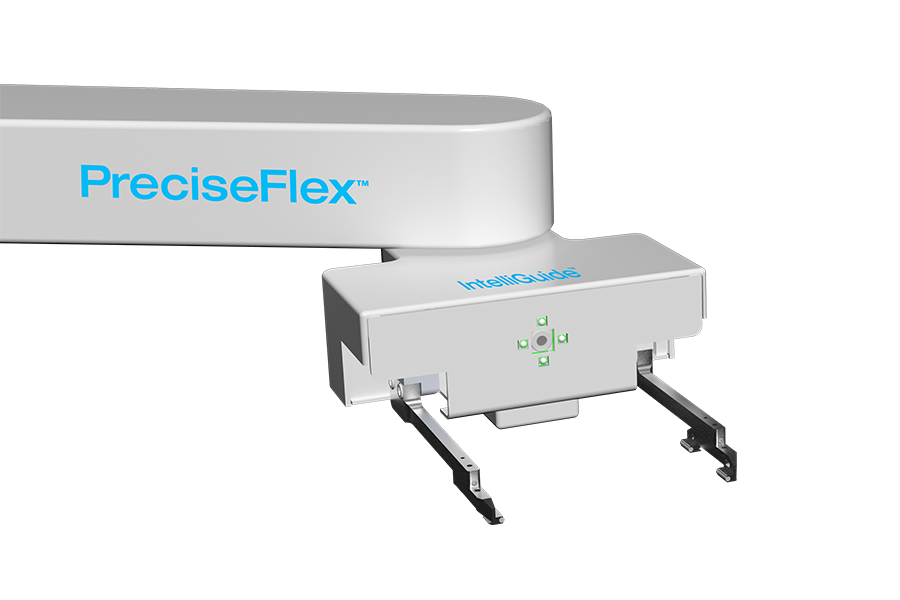

IntelliGuideTM Vision

Take your automation workflow to the next level with IntelliGuide™ Vision – the cutting-edge solution for seamless vision integration with PreciseFlex robots. Save time, minimize costs, and achieve unparalleled throughput.

Software

Command or program PreciseFlex robots your way. Use our API to control them from your scheduling or workflow software. Build no-code applications with GP Flow. Or program from our full-featured GPL. Manage all of them from Guidance Development Studio (GDS).

Mobile

PreciseFlex robots bring smart efficiency to mobile automation. With energy-saving performance that extends AMR runtime by 30%, built-in controls for space savings, and IntelliGuide™ Vision for rapid deployment, they’re engineered for seamless integration and stability on the move.

Key Benefits

- A no-risk way to extend to robot reach by up to 2.0 meters.

- Thousands have been sold and are deployed around the world.

- Plug and play with pre-engineered configurations – saves time and cost.

- c-Series linear rails (with blue end cap) are used for PreciseFlex c5 robots.

- Legacy linear rails (with white end caps) are used for PreciseFlex 400 and 3400 robots.

Product Features

- All cables and controls are contained inside the linear rail, which is equipped with drip proof covers and tape seals.

- Up to 700 mm/sec travel speed.

- Different mounting configurations for PreciseFlex 400 and 3400 robots. With the PreciseFlex c5 rotary column, only one mounting configuration is needed.

- Low power consumption.

IntelliGuideTM Vision

Simplify vision applications with IntelliGuide Vision. Cameras embedded in the gripper (forward and downward facing) enable less engineering effort, faster deployment, and shorter time to production. Factory calibrated and ready to use out of the box. Simply specify offset to gripper fingers.

Key Benefits

-

Embedded Cameras

Forward and downward-facing factory-calibrated cameras and vision systems provide precise, reliable imaging out of the box.

-

Auto-Teach

Minimize downtime by using Auto-Teach to automatically reteach locations and recovery from changes in the workspace—no wasted time reprogramming workflows.

-

Precise Object Location

Use the locator tool to quickly train objects and start picking from trays, fixtures, conveyors, and more.

-

Clear-Check

Use Clear-Check at the beginning of a workflow to determine if SBS plates are where they should be or to check for presence or absence of certain components of features on PCBAs and other workpieces.

-

Micro-Localization for Mobile Applications

The Auto-Teach function solves the micro-localization challenge for mobile applications and roll-up carts. No need to add bulky and expensive localization features for AMRs.

-

Extensible Vision Platform

We continue to add high-level, easy-to-deploy functions as we solve challenging problems with for our customers, removing the need to be a machine vision expert.

Key Features

Auto-Recovery when Change Happens

Automatic recovery and reteaching of locations when things shift in the workspace.

Auto-Teach

Read ArUco Markers and determine offsets to hotels, instruments, magazines, fixtures etc. Quickly recover from changes in workcell without reteaching tens or hundreds of locations.

Ideal for Roll-up Carts and AMRs

Easily locate objects in dynamic environments.

Image Capture

Capture time-stamped images when an event occurs and transfer for further analysis. Useful for trouble shooting of chain of custody.

Image Sharpness

Returns image sharpness that enables focus adjustment by moving the robot closer to, or farther away from, the target.

Object Locator

Geometric part locator tool for locating objects in 2D space. Quickly train objects and start picking from trays, conveyors, nests, etc.

How it Works

1. Set It Up

IntelliGuide Vision is factory-calibrated and pre-installed on your robot. Simply connect via Guidance Development Studio (GDS) and begin building your vision project and robot applications.

2. Automate Workflows

Use TCS API or GP Flow to execute your projects to perform Auto-Teach routines, Clear-Check, and Barcode Reading

3. Optimize and Evolve

Use the robust software to refine performance, troubleshoot with detailed image captures, and upgrade as your needs grow.

Redefine automation with vision

Fast Setup

The IntelliGuide Vision gripper comes factory-calibrated and preinstalled on the robot. It integrates seamlessly with GDS software, streamlining configuration and programming. This greatly reduces design and engineering time required to order, install, calibrate, and configure third-party vision systems, saving thousands of dollars.

Seamless Adaptability

Automatically recover and adjust to changes in dynamic workcells and easily incorporate roll-up carts into your workflow.

Improved Efficiency

Reduce engineering and teaching times, trimming weeks of deployment into mere hours, saving thousands of dollars.

Empowering users in laboratories and manufacturing, IntelliGuide Vision ensures you can focus on what matters—innovation and productivity.

Frequently Asked Questions on IntelliGuideTM Vision

What robots are compatible with IntelliGuide Vision?

It supports PreciseFlex Robots, including the PreciseFlex 400, Previse Flex 3400, PreciseFlex c10 robots, and the new PreciseFlex c3 and c5 robot models. It’s also compatible with our collaborative linear rails.

How does IntelliGuide handle workspace changes?

The auto-recovery feature automatically adjusts to changes in the workcell, eliminating time-intensive reteaching.

Can IntelliGuide Vision assist in traceability?

Yes, it offers advanced features like barcode reading, timestamped image capture, and precise chain-of-custody recording.

Is the system user-friendly for non-experts?

Absolutely! With a plug-and-play setup and intuitive programming via Guidance Development Studio (GDS), it’s designed for efficiency and simplicity.

How long does deployment take?

With its pre-calibrated setup and embedded tools, deployments occur significantly faster—saving you weeks of design and engineering time.

Can I upgrade my existing robot to use IntelliGuide Vision?

Yes. However, there are minimum revision requirements. Contact for more information.

Solutions

- Introducing GP Flow, a no-code, point-and-click application builder that simplifies how users deploy PreciseFlex robots. Configure, Link and Go!

- GP Flow enables users to quickly build applications and get their robot up and running. It is ideal for simple applications, with expanded capability using the Resource Toolbox. GP Flow statements are open source and customizable.

- Our full-featured GPL programming language retains all the functionality expected from power users.

- GP Flow, Resource Toolbox, and GPL all provide a seamless path from basic to advanced applications within GDS (Guidance Development Studio).

- Users also have access to our EtherNet/IP interface and TCS API.

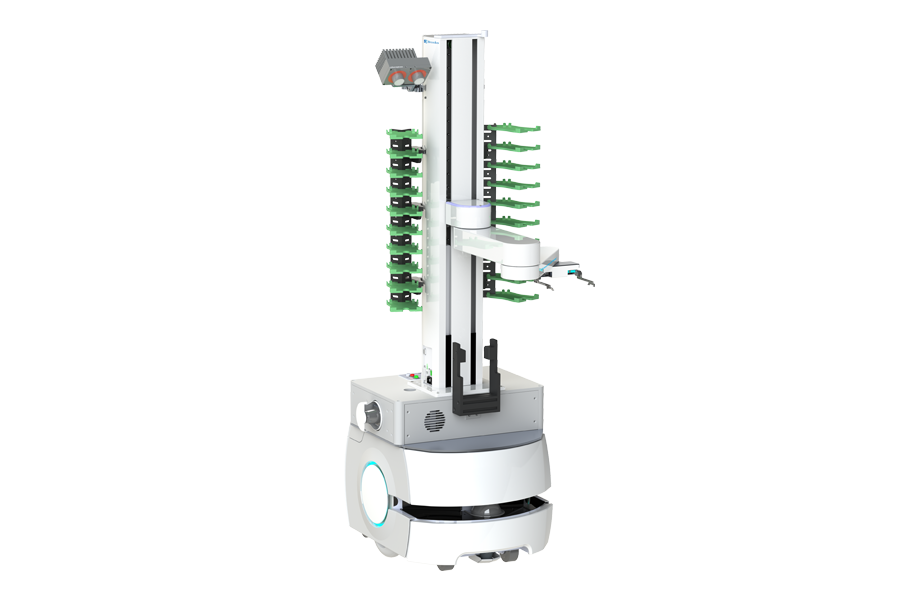

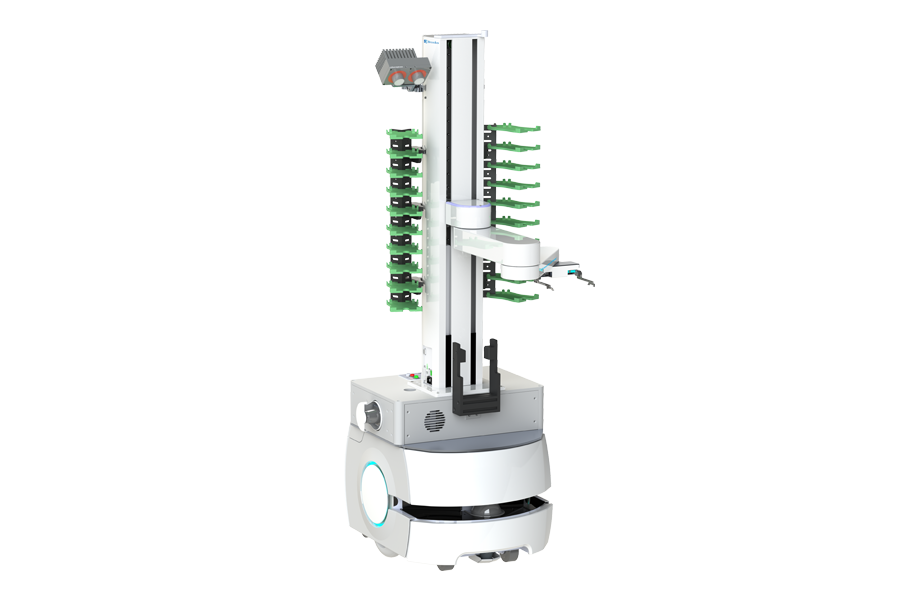

Mobile

PreciseFlex robots bring smart efficiency to mobile automation. With energy-saving performance that extends AMR runtime by 30%, built-in controls for space savings, and IntelliGuide™ Vision for rapid deployment, they’re engineered for seamless integration and stability on the move.

Key Benefits

- Fast and easy deployment unlocks the best ROI

- Longest AMR runtime improves ROI

- Augments workforce and overcomes labor shortages

- Reduces repetitive stress injuries and frees employees for more meaningful work

*Always refer to the AMR documentation and perform analysis of the center-of gravity

Wide Range of Applications

The PreciseFlex 3400 and PreciseFlex c10 robots are being used in laboratory automation, electronics test and handling, tote handling and transport, and even indoor farming.

30% Longer AMR Stability

Reduced energy usage and extended runtime in mobile applications is critical. Some models are available with DC power option, saving even more power. PreciseFlex robots enable 30% longer AMR runtime.

Optimal AMR Stability

The unique configuration of PreciseFlex robots with horizontal articulation for the major axes and a tall Z-axis provide the optimal AMR stability, by keeping the center-of-gravity (CG) over the AMR*. As other traditional robots and cobots) reach out beyond the AMR, the CG tends to also extend beyond the AMR resulting in a tipping risk.

Embedded Controls and DC Power Option

All PreciseFlex robots have embedded controls. That means, no external controller and bulky robot cables to deal with. The PreciseFlex 3400 robot is also available with a DC Power Option, making for a much cleaner AMR system.

Micro-Localization with IntelliGuide Vision

Most AMRs can localize to ±2-5 cm, and that’s highly dependent on the environment. IntelliGuide Vision on PreciseFlex robots enable micro-localization of ±0.5 mm. With IntelliGuide Vision, the cameras are calibrated and installed from the factory. They’re ready to use, out-of-the-box.

Product Features

1. Highest Workspace Density

Reach into machines and shelves with tall Z-axis and slim arm design.

2. Save Time and Increase Reliability

With fully-integrated Servo Gripper (optional).

3. Z-Axis Range of Motion

750 and 1160mm

4. Highest Throughput

Low collision forces enable without sacrificing safety.

5. Save Valuable Floorspace

With compact footprint and embedded controller.

6. Extend Robot’s Reach

With fully-integrated Collaborative Linear Rail (optional).

7. Highest Reliability

With MTBF of 125,000 hours

Start Automating Today

Explore how PreciseFlex can accelerate deployment, reduce engineering overhead, and scale with your applications — from OEM systems to high-density workcells.