Automate PCB Testing Without the Cost of an Inline System

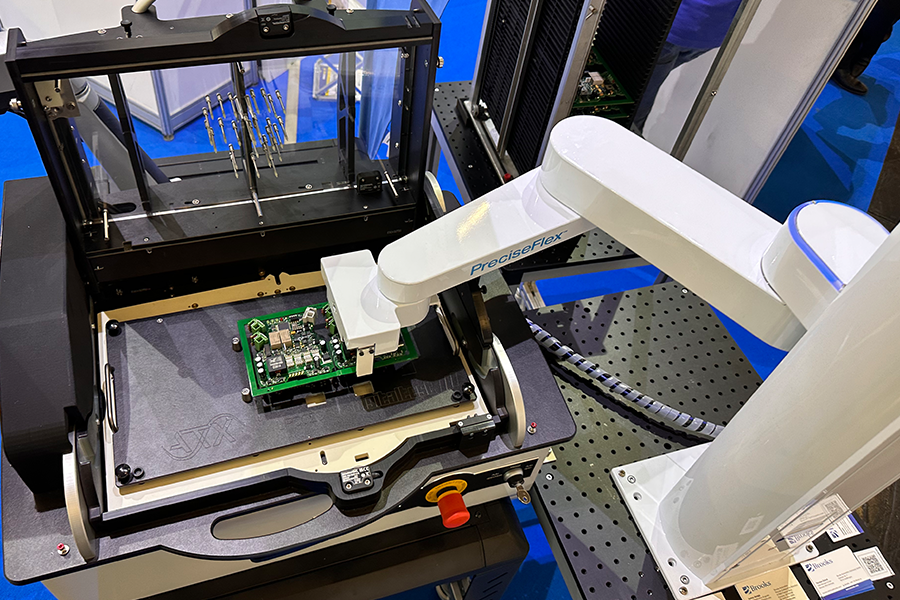

Many PCB test lines can’t justify bulky inline systems. PreciseFlex robots give you the same consistency with more flexibility in the footprint of a human operator.

Manual PCB Test Loading is Holding You Back

The real cost isn’t seconds – it’s wasted throughput.

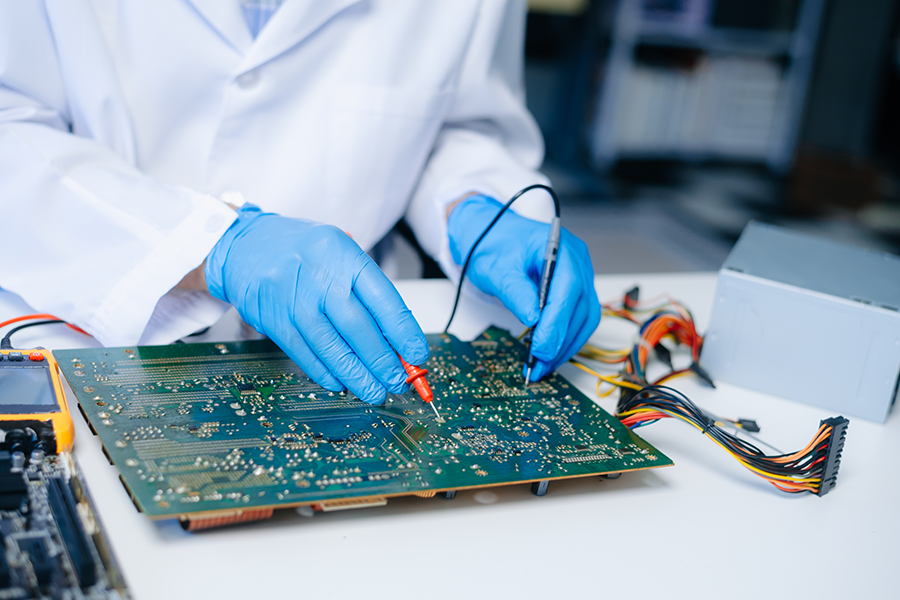

Every board an operator loads by hand adds hidden costs: idle testers, inconsistent results, and wasted labor. Skilled people stand around waiting while expensive test equipment sits underutilized.

Inline automation isn’t always the answer.

Bulky inline systems demand high capital, force layout changes, and lock you into rigid workflows that most mid-volume operations can’t justify.

And “cheap” robots?

They often fail in real test environments. Reliability issues, downtime, and poor support wipe out any savings fast.

Automation that fits your workflow - not the other way around.

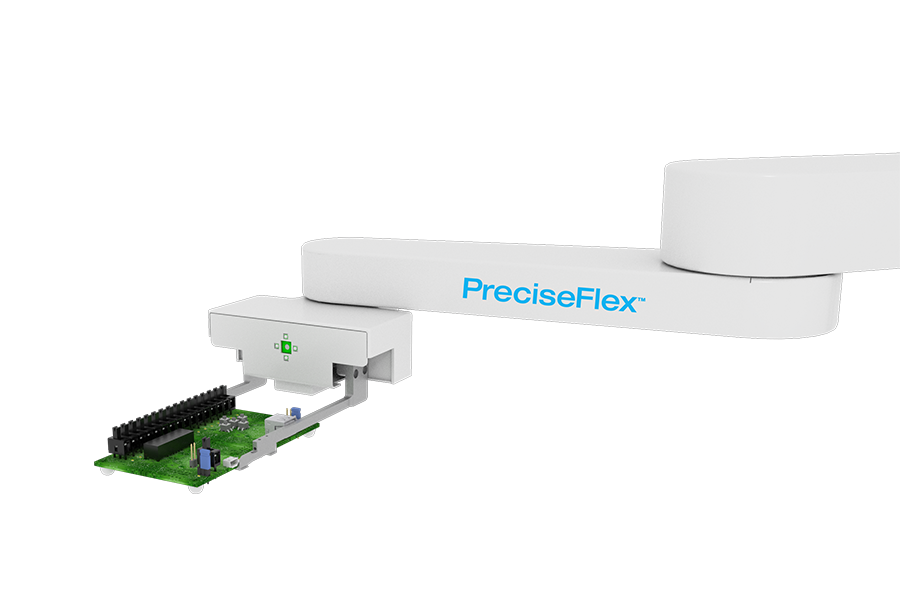

PreciseFlex robots deliver inline-level precision without the cost, space or disruption of a full system redesign.

Human-scale by design.

They fit where your operators already stand — same footprint, same workflow — so you can deploy automation without re-engineering your entire line.

Proven in real-world test environments.

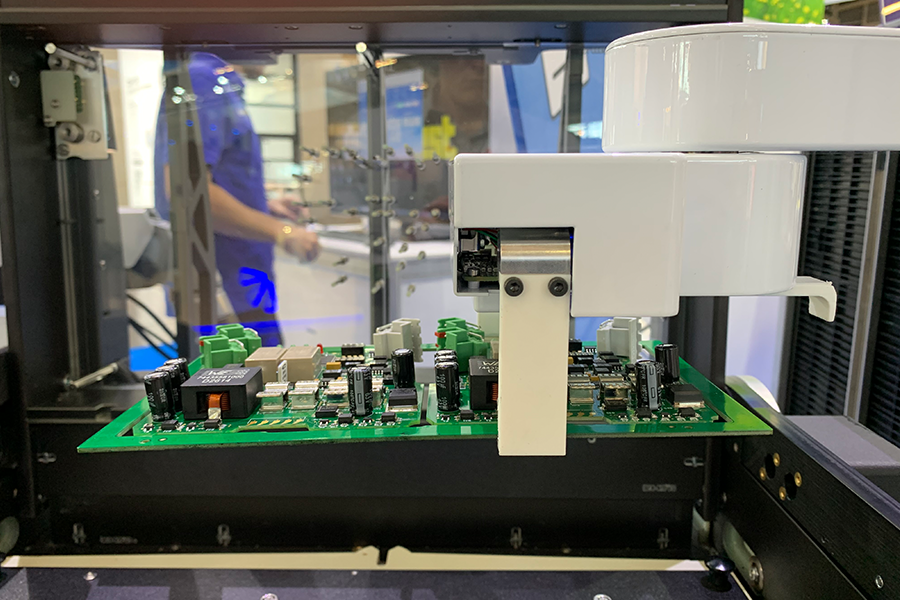

With flexible, precise motion and an integrated controller, PreciseFlex robots handle delicate boards and tight test cells reliably, cycle after cycle.

Electronics Test & Handling Automation

Boost throughput. Reduce labor costs. Improve quality.

PCB Handling

Automate PCB handling without the risk of damage or space headaches.

Proven Across PCB Testing Methods

Whether you’re running quick ICT checks or hours-long burn-in cycles, PreciseFlex robots handle each board with the same repeatable precision. That’s why electronics manufacturers trust them across the full range of PCB test processes.

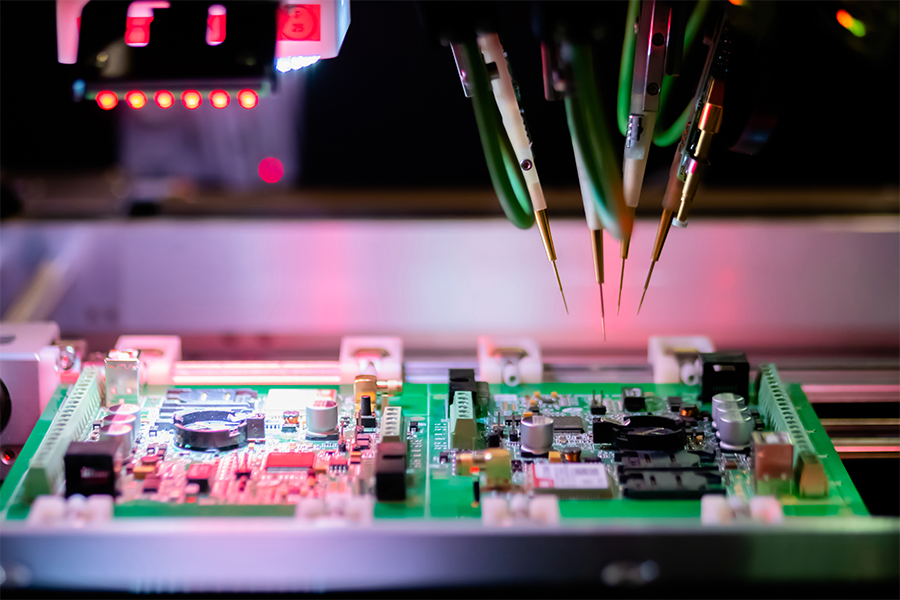

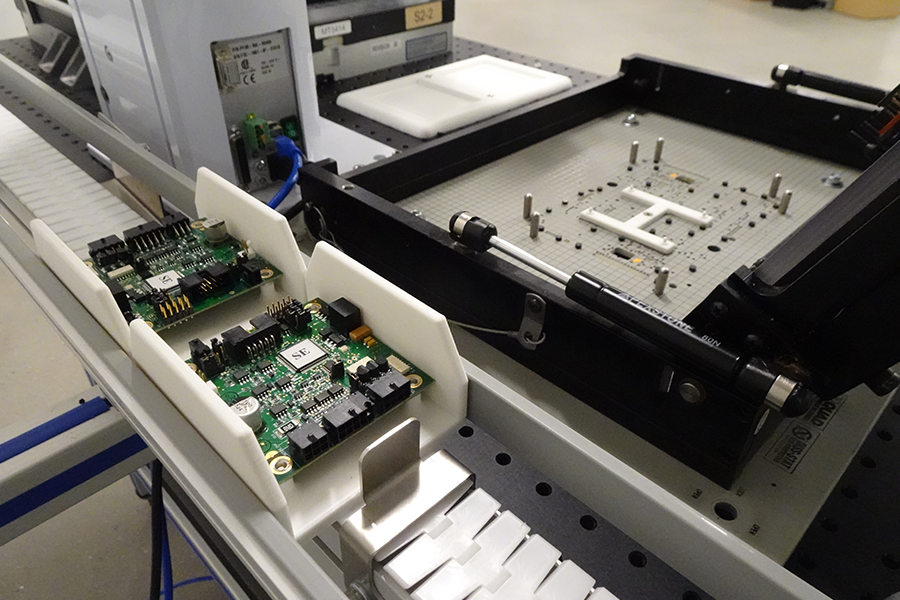

In-Circuit Testing (ICT)

Consistent, gentle placement protects pins and connectors while ensuring perfect alignment with test fixtures.

Functional Testing (FCT)

Accurate positioning guarantees full contact so test results are reliable, not rework.

Flying Probe Testing

Delicate boards? No problem. PreciseFlex handles fragile PCBs carefully, even in tight clearances and long test cycles.

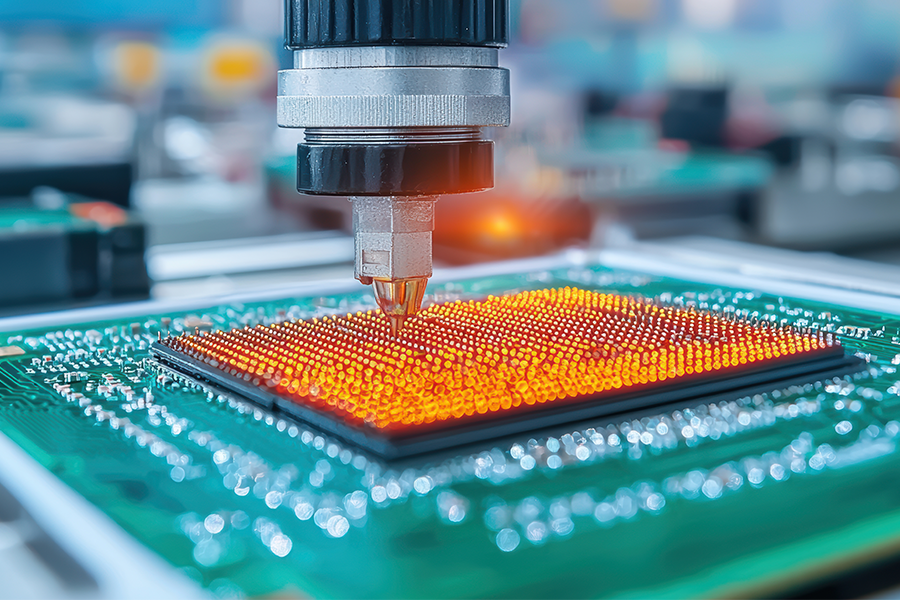

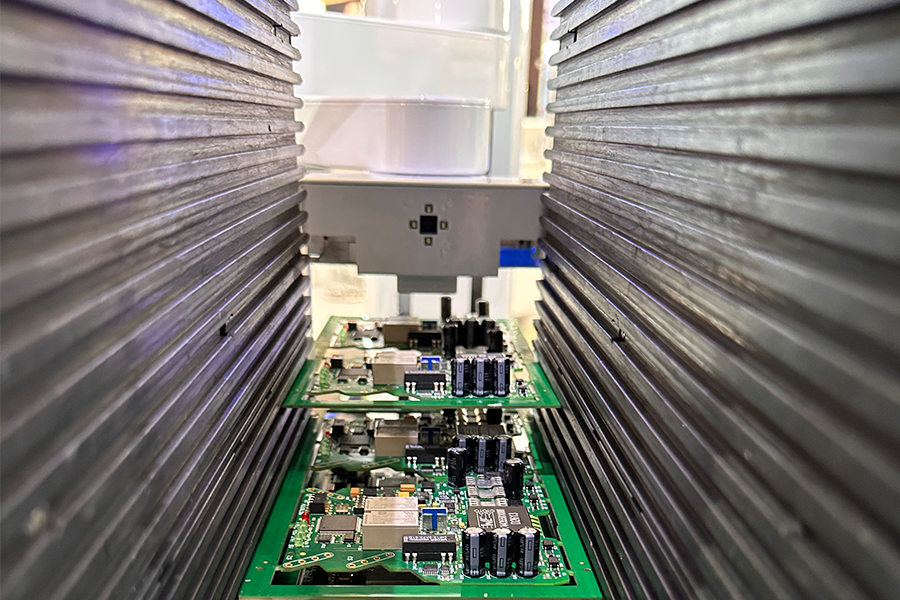

Burn-In Testing

Repeatable handling into ovens and chambers reduces thermal stress and eliminates damage from rushed manual loading.

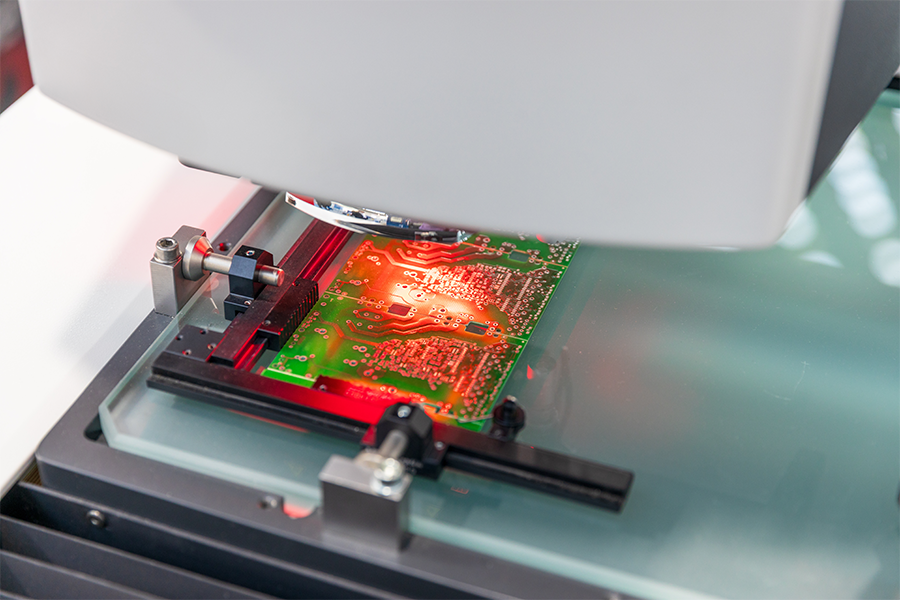

Automated Optical Inspection (AOI)

Stable, precise handoffs keep vision systems calibrated and inspection results consistent.

X-Ray Inspection

Smooth, low-inertia motion protects solder joints while feeding boards into enclosed or shielded equipment.

Robots Built for Real PCB Test Stations

Whether you’re automating a single ICT bench or running a multi-station test line, there’s a PreciseFlex model built to match your workflow.

Each delivers human-scale automation: compact design, precise motion, and easy integration into space-constrained electronics environments.

Unlock Efficiency in Electronics Manufacturing

Discover how PreciseFlex robots are transforming electronics test operations. This white paper explores the urgent challenges facing manufacturers—labor shortages, rising wages, and shrinking product lifecycles—and presents a compelling case for automating manual test processes like ICT, FCT, and burn-in. Learn how automation boosts throughput, improves quality, reduces costs, and enables strategic reshoring, all while delivering strong ROI and scalability.

Results You Can Measure

Keep testers busy — not idle.

Most ICT and functional testers sit idle between cycles. PreciseFlex robots keep them loaded, increasing uptime, throughput and eliminating hidden bottlenecks.

Free your people for higher-value work.

Stop paying skilled operators to stand in front of idle testers. With robots handling repetitive loading, your team can focus on quality checks, setup, and troubleshooting.

Do more with the space you have.

Inline systems eat square footage. PreciseFlex robots fit right where your operators work, so you get automation without redesigning your floor plan.

Protect yield with consistent handling.

Misaligned or mishandled boards cost time and money. Robots load PCBs with the same precision every time, helping you maintain high first-pass yield rates.

Frequently Asked Questions

Do I need to redesign my test station?

No. PreciseFlex fits where your operators already stand, with no major layout changes.

Will it work with my testers and fixtures?

Yes. PreciseFlex integrates seamlessly with ICT, FCT, AOI, X-Ray, burn-in, and more.

How does it handle board variability?

IntelliGuideTM Vision aligns boards in real-time, even in high-mix environments.

Do I need coding expertise to run it?

No. GP Flow is no-code. Most teams configure workflows in hours, not weeks.

How do I know which model is right?

That’s what our application engineers are here for: to review your setup and recommend the right fit.