Best Practices for PCB Handling When Quality and Throughput Are on the Line

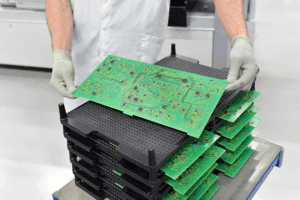

The difference between a reliable printed circuit board and one that fails in the field often comes down to how it’s handled on the line. A small flex, stray charge, or single fingerprint can introduce defects that stay hidden until later in production. As components shrink and boards become more complex, handling is now as critical to quality as assembly or testing.

Let’s explore the main ways to keep PCB quality high and avoid damage from handling. You’ll also learn how automation can make production more consistent, increase yield, and keep throughput steady.

Causes of PCB Damage During Production

Most defects that hurt yield come from small, predictable handling mistakes repeated many times during a shift. Each handoff in the production line introduces another chance for damage, and the risks fall into a few familiar categories.

1. ESD Events (Latent and Catastrophic)

Even minor electrostatic discharges can degrade component reliability. Static from people, ungrounded carts, or unchecked wrist straps can cause damage that shows up later. The highest risk comes from simple actions like placing a board in a fixture, plugging in a cable, or unwrapping it without proper grounding.

2. Mechanical Stress and Strain

Boards are thinner and more densely populated than in the past, which makes them sensitive to flex and pressure. Grabbing a board at two points, lifting it from the middle, or inserting it at an angle can cause micro-cracks or warp the substrate. Misaligned fixtures or over-tightened clamps can bend the board, leading to uneven surfaces and poor test connections.

3. Contamination and Residues

Fingerprints, dust, and leftover flux are common causes of cosmetic and electrical defects. Oils or glove powder can affect soldering, and small bits of debris can cause false readings during automated inspection. Clean handling surfaces and regular glove changes are often overlooked but essential controls.

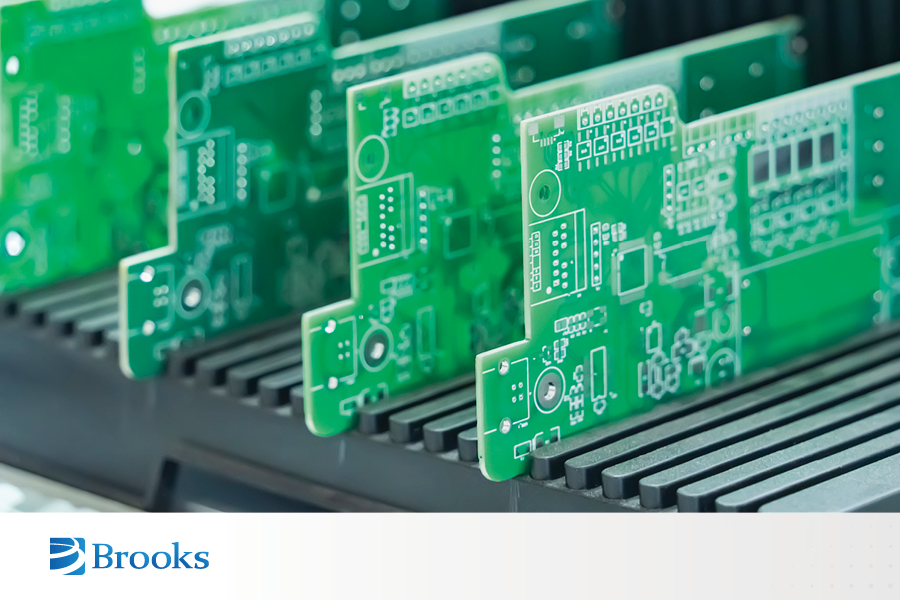

4. Storage and Transport Pitfalls

Boards can get damaged by movement or static electricity between steps if magazines are worn, racks aren’t ESD-safe, or carts vibrate too much. Moisture is another risk. Poor storage or skipping bake cycles for sensitive parts can cause the board to blister or separate during reflow.

5. Handoff Hotspots

PCB assembly, inspection, rework, and final packout all involve repeated connector cycles and fixture changes. These manual interactions are where small errors compound, increasing wear and variability.

6. Diagnostics That Reveal Handling As the Root Cause

Rising defect rates or visible wear on connectors and boards usually point to inconsistent handling. Reviewing ESD logs, defect data, and fixture maintenance records helps identify the source before failures spread. Once the root cause is clear, manufacturers can target improvements and decide which handling steps are best automated.

Standardizing PCB Handling to Protect Quality and Reduce Defects

Standardizing PCB handling reduces variation and rework. Maintaining that consistency is getting harder as line speeds rise and skilled labor declines.

- ESD and mechanical controls: The first step in protecting boards from damage is setting up and maintaining an Electrostatic Protected Area (EPA). Grounding straps, ESD-safe carts, compliant packaging, and routine checks help control static discharge. Clear handling rules are essential. Grip boards by the edges, guide connectors gently, and maintain fixtures to prevent flex, stress, and rework.

- Operator discipline: Using powder-free gloves and marking safe “touch zones” helps workers handle boards the same way every time. Short, focused training sessions reinforce these habits. Adding barcode or RFID tracking makes it easier to trace each board through production and spot where handling differences occur.

- Storage and transport: Choosing the right magazine size, controlling humidity, and keeping moisture levels stable protect boards between steps. Tracking first-pass yield, ESD audit results, and handling incidents helps measure how well the process is working.

Even with strong procedures, people can only stay consistent for so long. Repetitive handling adds little value but carries a high risk of damage.

To protect quality and maintain throughput, more manufacturers are turning to automated PCB handling systems that free skilled workers for higher-value tasks.

Why Manual Handling Bottlenecks Limit Throughput

As production volumes grow and product mixes increase, manual handling often becomes the hidden constraint on throughput. Even in well-run facilities, human variability and fatigue create inconsistencies that automation prevents.

Variability That Scales With Headcount

Every operator handles boards a little differently. Grip strength, insertion angle, and pacing vary from person to person and across shifts. Fatigue, turnover, and varying skill levels increase process variation. The result is inconsistent ICT cycle times, extra AOI rechecks, and fixture alignment issues. As headcount increases, so does process variability.

Capacity and Flow Constraints

Manual loading and unloading create natural pauses in production flow. A single operator may manage multiple testers or inspection systems, resulting in queues and idle equipment. In high-mix operations, fixture swaps and labeling errors extend cycle times further. These small inefficiencies accumulate, reducing the effective capacity of otherwise capable equipment.

Labor Economics and Risk

Repetitive manual tasks increase ergonomic strain, fatigue, and turnover. This cycle raises both hiring and training costs. When experienced operators leave, process knowledge and stability go with them. The financial impact extends beyond labor. Each handling mistake risks latent ESD damage, connector wear, or contamination that can surface later as warranty claims or field returns.

High-Mix Realities

Frequent product changeovers increase the chance of handling errors, especially when schedules are tight. Missing a line-clearance step or rushing a fixture swap can lead to rework or retest. Even careful operators struggle to maintain precision when parts, tooling, and test setups change multiple times per shift.

Manual handling still has a place in low-volume or prototype builds where human judgment and flexibility matter more than cycle time. In most production settings, however, stability and consistency depend on automating repetitive tasks to replace human variation with controlled, repeatable motion.

Automated PCB Handling for Consistency, Yield and ROI

Automation delivers the greatest improvements when it targets repetitive, high-risk handoffs. Replacing manual loading and transfers with robotic systems reduces defects, improves throughput, and stabilizes quality across shifts.

1. Where Automation Delivers First Value

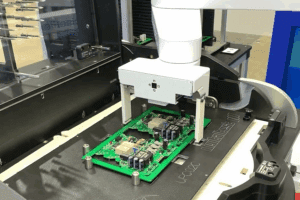

Early automation projects typically focus on processes where precision and consistency matter most. Robotic loading and unloading at ICT, FCT, AOI, and burn-in stations remove variability from test results and prevents connector wear. Robots also handle board transfers between conveyors, depaneling, coating, curing, and inspection stations. Adding automated serialization and label placement strengthens traceability without interrupting production flow.

2. Gentle-by-Design Mechanics

The best systems are engineered for delicate work. ESD-safe end-effectors and edge-grip or vacuum carriers keep sensitive assemblies protected. Compliant motion control adds another layer of safety. Vision or fiducial alignment ensures accurate placement, and controlled acceleration and deceleration prevent flexing or stress on fine-pitch components. Many setups now include inline barcode verification to eliminate manual scanning errors.

3. Cell Design and Tooling

Each cell should support consistent, repeatable handling.

- Standard carriers or pallets maintain planarity and alignment between stations.

- Quick-change grippers and modular sensors simplify maintenance and support variant builds.

- Alignment guides, datum references, and error-proof interlocks prevent loading mistakes before they happen.

4. Integration and Controls

Automation works best when all systems communicate. Robots can connect with testers and inspection stations through digital I/O or fieldbus links so each step happens in sync. Linking automation with MES software enables recipe control, serialization, and live performance tracking.

Vision tools make this connection even stronger. They help robots locate parts, align boards, and guide connectors accurately even when positions shift slightly. With IntelliGuide™ Vision, robots detect and align PCBs in real time even when tray positions change or boards vary, improving placement accuracy and reducing handling errors.

Safety is also built into modern systems. Collaborative robots with limited power and force can safely share space with people. Light curtains and compact layouts make it easier to add automation in tight test areas.

For advanced vision integration, Brooks offers IntelliGuideTM Vision. This 2D machine-vision software locates, identifies, and measures parts for motion guidance. It is used for tasks such as barcode scanning, locating fixtures, cassettes and magazines with Auto-Teach and detecting the presence or absence of PCBAs with Clear-Check in electronics manufacturing.

5. Performance You Can Measure

Once installed, automated handling quickly shows measurable benefits:

- Improved first-pass yield (FPY) from more accurate placement and consistent contact.

- Reduced DPMO by eliminating ESD and contamination risks.

- Longer connector life and more predictable maintenance intervals.

- Higher tester utilization, smoother product changeovers, and lower cost per board.

6. ROI and Adoption

Most manufacturers begin with a single pilot cell and evaluate results before expanding. They track first-pass yield, cycle time, and rework rate over 60 to 90 days to confirm steady improvement. Once the process proves reliable, the same setup can be replicated across more lines.

Automation with collaborative robots creates measurable value by improving consistency and reducing downtime. The main savings come from:

- Fewer defects and less rework

- Operators redeployed to higher-value tasks

- Faster product changeovers

- Better use of floor space and test equipment

- Lower long-term labor and maintenance costs

Cobots are energy efficient, require little maintenance, and can be installed quickly. These advantages help manufacturers achieve faster returns on investment. Setting clear performance goals and reviewing results regularly allows teams to track progress and build confidence before expanding automation to additional lines.

Interested in real-world results?

Brooks customers have seen measurable gains from automating PCB handling:

- Payback in 16–20 months across regions

- Fewer handling errors and warranty claims over $1,000 per incident

- Better use of existing floor space and test resources

Learn more about automating electronic handling in our whitepaper.

7. Risks and Mitigations

Automated handling requires planning and setup to match each product type. Thin or flexible boards may need custom carriers and slower movement to prevent flex. Connectors with unusual shapes can be handled using vision alignment or gentle force control.

For lines that run many product variants, quick-change grippers and recipe management keep transitions smooth. Regular preventive maintenance keeps sensors and motion systems accurate over time.

Strong training and clear safety guidelines help operators and engineers manage the system confidently and keep production running smoothly.

8. Vendor Selection

Choosing the right partner matters as much as choosing the right robot. Look for integrators with ESD handling experience, strong references in electronics testing, and proven gentle-motion control. Open software integration, operator training, and after-sale support are essential.

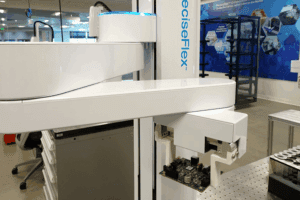

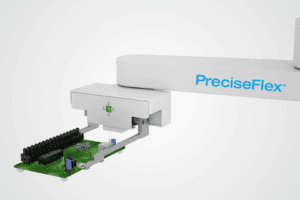

Collaborative systems like Brooks PreciseFlex™ robots are designed specifically for compact test cells. They deliver ESD-safe, repeatable motion that protects PCB quality while improving throughput.

Protecting PCB Quality Through Smarter, Automated Handling

Consistent, ESD-safe handling is the foundation of reliable PCB manufacturing. Manual processes, even when well-documented, can’t keep pace with today’s throughput targets or complex board designs. Standardizing each touchpoint helps reduce variability, but true consistency comes from automation.

By automating critical handoffs manufacturers can stabilize cycle times, extend fixture and connector life, and improve first-pass yield across shifts.

PreciseFlex robots combine precise motion control with a compact, ESD-safe design. This combination enables gentle, repeatable PCB handling in dense test environments. They allow production teams to protect quality while meeting throughput goals. Skilled operators are then free to focus on higher-value tasks that move the line forward.

Start Automating Today

Learn how PreciseFlex™ robots can improve handling consistency and throughput in your test cells. Discover practical ways to raise quality standards without disrupting your existing production setup.