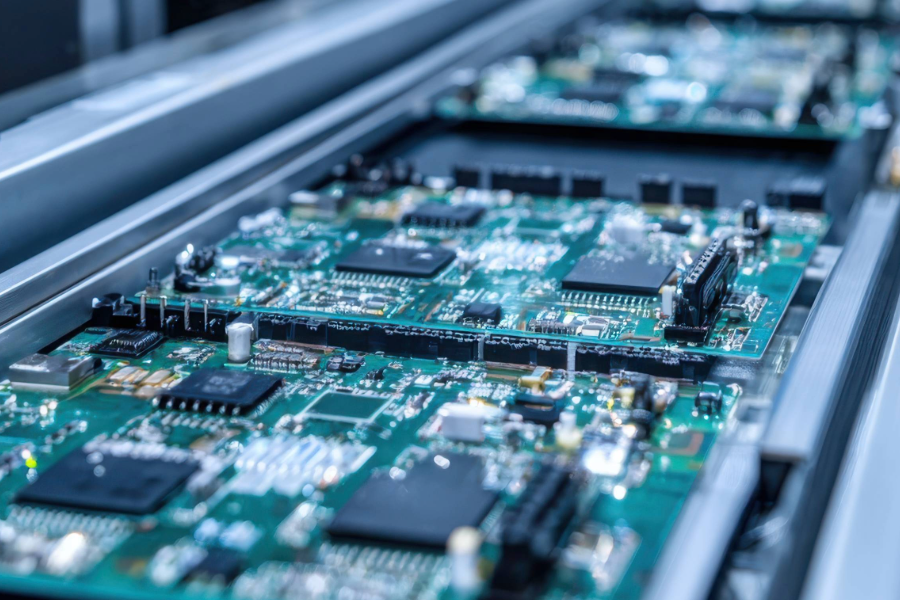

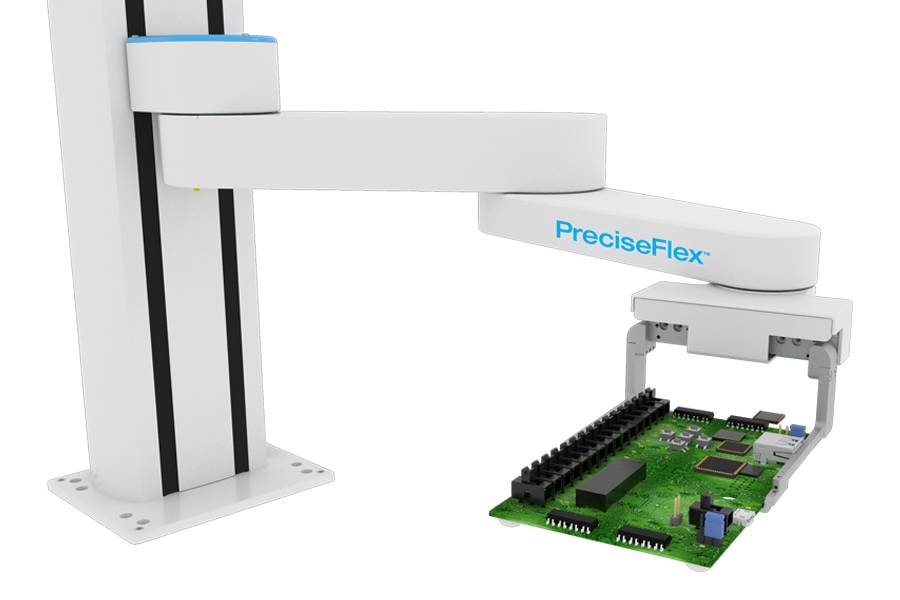

Automate PCB Handling Without the Risk of Damage or Space Headaches

Manual transfers waste labor and risk ESD or handling damage. PreciseFlex robots move boards gently and consistently in the same footprint as your operators.

Still Moving PCBs by Hand?

It’s Costing You More Than You Think

The hidden price of manual handling

Every time an operator moves a board, you introduce risk — ESD damage, bent connectors, contamination. Add up the wasted labor and scrap and “manual” becomes one of the most expensive steps in your line.

Conveyors and gantries don’t solve it.

They’re rigid, costly, and force you into layouts that break when products change. High-mix electronics lines need flexibility, not fixed hardware.

And relying on people?

Shifts change. Skill levels vary. Errors creep in. Manual variation creates bottlenecks and defects that ripple downstream into rework, delays and lost yield.

PCB Testing

Automate PCB testing without the cost of an inline system.

Electronics Test & Handling Automation

Boost throughput. Reduce labor costs. Improve quality.

Watch PreciseFlex Robots handle large and delicate PCBs.

Automation that adapts to your workflow — not the other way around

Conveyors and gantries lock you into rigid layouts. Manual handling risks damage and wastes labor. PreciseFlex robots give you the flexibility and precision your line actually needs.

The PreciseFlex Way to Automate PCBA Handling

Human-scale by design.

PreciseFlex robots fit where your operators already work, same footprint, same workflow, so you can deploy automation without redesigning your floor.

Safe for sensitive boards.

With low-inertia motion and servo-controlled grippers, boards move gently and consistently, reducing ESD events, misalignment and handling damage.

Proven across electronics operations.

From tray loading to packaging to line transfers, PreciseFlex robots keep production flowing smoothly. Helping manufacturers scale output, protect yield, and relieve labor pressure.

Robots Built to Handle Boards Safely in Any Setup

Whether you’re moving PCBs between benches, trays, conveyors, or packaging cells,

there’s a PreciseFlex robot sized and configured to fit your workflow.

Each model delivers human-scale automation: compact design, precise motion, and simple integration into tight electronics spaces.

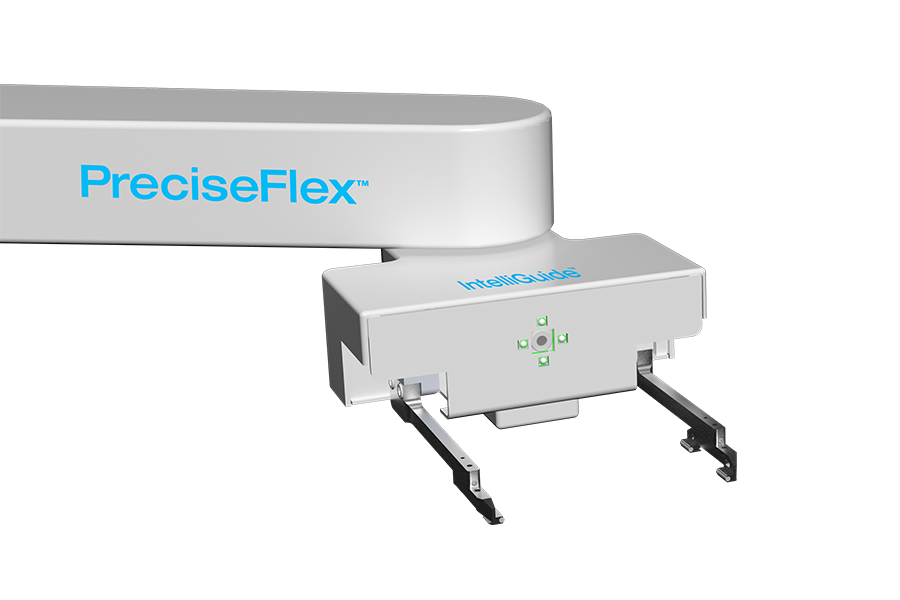

PreciseFlex 3400

Space-saving design with IntelliGuideTM servo or vision gripper, ideal for electronics handling and other applications needing a bit more carrying capacity. 3 kg payload (without gripper).

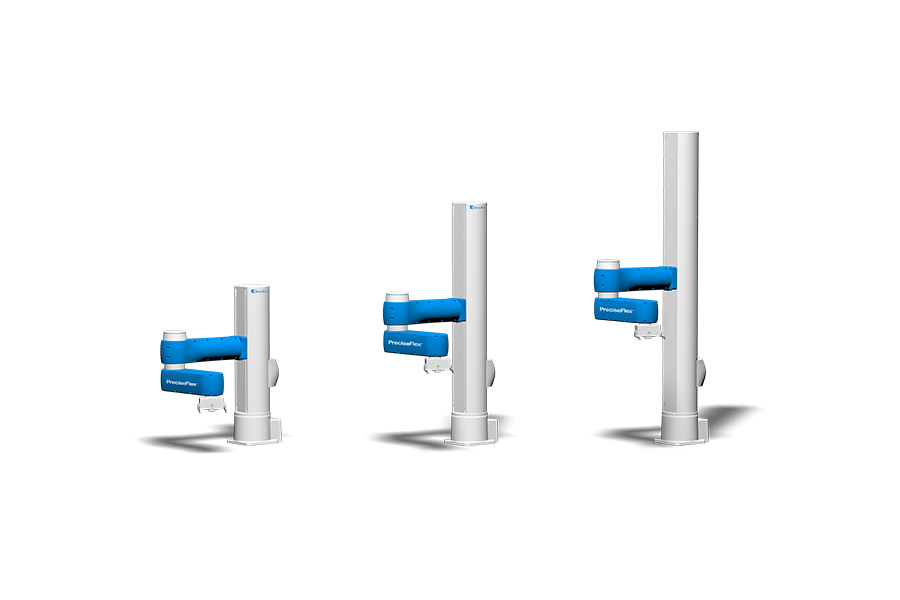

PreciseFlex c5

Cylindrical working volume for higher instrument density and higher horizontal reach for stacked testers and racks. 5 kg payload (without gripper).

PreciseFlex c10

Similar to PreciseFlex c5 with taller working volume and horizontal reach. 10 kg payload (without gripper).

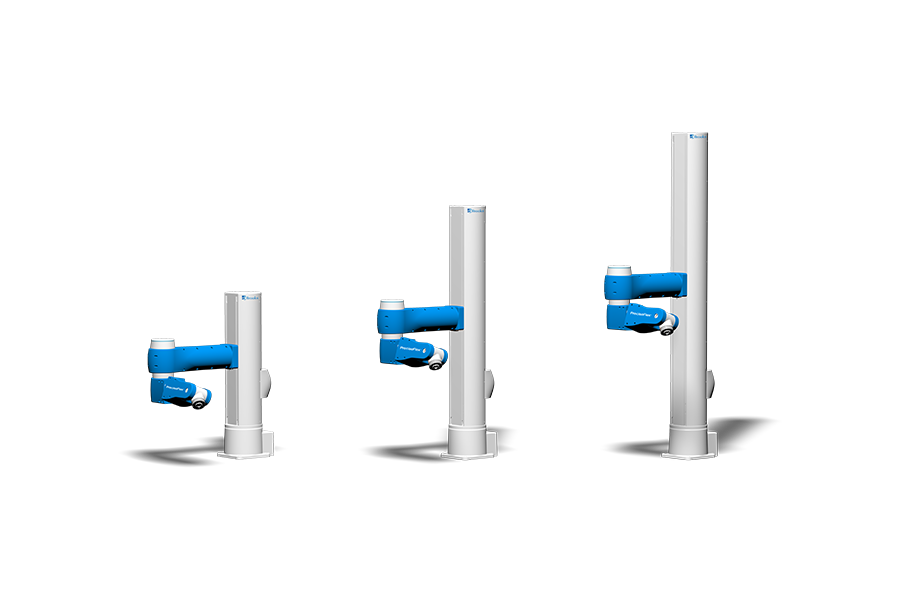

PreciseFlex c8A

Cylindrical working volume for higher workspace density with 6-axis articulation. 8 kg payload (without gripper).

Smarter than just a robot

Whether you’re moving PCBs between benches, trays, conveyors, or packaging cells, there’s a PreciseFlex robot sized and configured to fit your workflow.

Each model delivers human-scale automation: compact design, precise motion, and simple integration into tight electronics spaces.

IntelliGuideTM Vision

Boards don’t always land where they should. That’s why PreciseFlex sees what it’s doing.

With IntelliGuideTM Vision, the robot detects and aligns PCBs in real time — even when tray positions shift or boards vary between cycles. The result: precise placement, fewer errors and smoother handling across your line. Embedded cameras for auto-teach, barcode reading, and object localization.

GP Flow no-code Software — Application Builder

GP Flow lets you set up PCB handling workflows visually, no coding required.

Define paths, gripper actions, tray handling, and conveyor steps in minutes, not weeks. Adjust workflows easily as board sizes, tray formats, or processes change.

With built-in EtherNet/IP and PLC support, GP Flow connects seamlessly into your existing equipment. Anyone on your team can get robots running quickly and keep them flexible as your production evolves.

Advanced Servo Grippers

Gentle with boards. Firm with consistency.

Our servo grippers apply just the right force for delicate PCBs, protecting components, connectors and edges. They adapt to different tray formats and board types, giving you secure, repeatable handling without the damage risks of generic grippers.

Unlock Efficiency in Electronics Manufacturing

Discover how PreciseFlex robots are transforming electronics test operations. This white paper explores the urgent challenges facing manufacturers—labor shortages, rising wages, and shrinking product lifecycles—and presents a compelling case for automating manual test processes like ICT, FCT, and burn-in. Learn how automation boosts throughput, improves quality, reduces costs, and enables strategic reshoring, all while delivering strong ROI and scalability.

Free up operators for critical work

Stop tying up skilled workers with repetitive transfers. PreciseFlex robots handle the low-value moves so your team can focus on inspection, setup, or diagnostics.

Protect boards from damage or contamination

Manual handling risks ESD, misalignment, and stress on fragile components. Robots move boards consistently and safely, reducing scrap and rework.

Fit automation into tight production zones

No need to redesign your floor plan. PreciseFlex robots fit in the same footprint as your operators, delivering automation without infrastructure changes.

Keep production moving across shifts

With consistent handling and flow, PreciseFlex reduces downtime and keeps your line running smoothly — even during staffing shortages or off-hours.

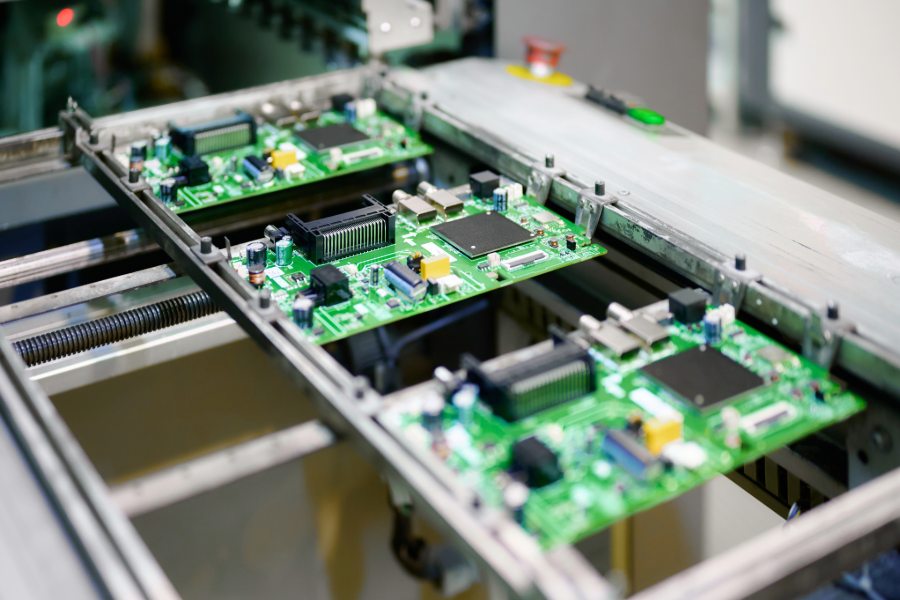

PCB Handling Tasks Simplified with PreciseFlex Robots

Whether you’re transferring boards between machines or loading trays for cleanroom transport, PreciseFlex robots bring consistency, control, and safety to every handling step.

Tray Loading and Unloading

Move PCBs into and out of JEDEC trays, carriers, or custom holders with precision. Perfect for packaging, cleanroom transfer, or in-process storage.

Conveyor-to-Conveyor Transfers

Bridge conveyors or move PCBs between belt systems without introducing stress or misalignment.

Workstation Buffering

Automate intermediate handling to balance line flow and reduce idle time between process steps.

Packing and Final Assembly Support

Place finished PCBs or subassemblies into packaging trays or test containers while maintaining ESD safety.

Sorter and Bin Picking

Pick and place PCBs from stacks or bins into defined sequences or queues, ideal for high-mix, low-volume production.

Cleanroom and ESD-Sensitive Handling

Maintain control in sensitive environments with robots designed to minimize contamination risk and support ESD-safe operation.

Frequently Asked Questions

Do I need to redesign my line to add a PCB handling robot?

No. PreciseFlex robots fit directly into existing workflows. Whether you’re transferring boards, loading trays, or supporting packaging.

Can your robots handle different PCB sizes or tray types?

Yes. IntelliGuide™ Vision and servo grippers adapt to variable board dimensions, positions, and carriers, making them ideal for high-mix environments.

How do these systems work in ESD or cleanroom environments?

PreciseFlex robots are already trusted in sensitive labs and semiconductor settings. Their low-particle design and gentle motion make them well-suited for ESD and cleanroom handling.

What kind of integration is required with our existing automation?

Each robot has embedded controls and EtherNet/IP support for easy PLC communication. With GP Flow’s no-code interface, most users set up workflows without programming.

How do I know which system is right for my operation?

Our application engineers review your layout, board specs, and throughput goals to recommend the best model and configuration.

Ready to Automate PCB Handling Without the Risk?

PreciseFlex robots deliver safe, flexible, and space-efficient automation, proven in electronics lines worldwide.